Hard, crusty layers that cling tenaciously in the tall oil plant are a pain in the butt. Just like that kettle used to boil hard water for a long time without cleaning; the white, chalky substance that forms on the inside is similar to the scale buildup in the tall oil plant... and the tea tastes bad.

What is going on?

When scale reaches its solubility limits in a tall oil plant, it means the concentration of scaling compounds in the liquid phase becomes so high that they can no longer remain dissolved. As a result, these compounds start to crystallize and form solid deposits. This clingy layer acts as an insulating barrier, potentially leading to operational inefficiencies, increased energy consumption, and the need for frequent maintenance and cleaning.

What are we dealing with?

Scale in the tall oil plant, primarily composed of inorganic compounds, reaches its solubility limit during the evaporation process, leading to deposition on surfaces. The scale that clogs the inlets to the tall oil storage tank and acidulation reactor tank primarily includes components such as spent acid (also known as brine), lignin, and solid gypsum (calcium sulfate). Although phase separation can facilitate the removal of most unwanted soap fractions, the presence of a lignin layer can slow down the settling process and inadvertently capture some of the crude tall oil, contributing to scale formation and clogging

Is this your situation?

| Operational Downtime | Removing scale often requires taking equipment offline for mechanical or chemical cleaning. This downtime can be costly in terms of lost production and labor expenses for cleaning and repairs. |

| Reduced Flow Efficiency | Scale build-up can narrow the internal diameter of pipes and outlets, leading to reduced flow, increased pressure drops, and the potential for blockages. This can cause inefficiencies in the tall oil separation process and increase the energy required for pumping and circulation. |

| Increased Yield and Improve Quality Control | Benefits of ultrasound also include an increased yield by improving phase separation between the tall oil, lignin and acidulated water. Address Inconsistent or inadequate processing due to scale effects can lead to variability in the quality of the tall oil produced, affecting its market value and utility in further applications. |

| Decreased Equipment Lifespan | Repeated scaling and the subsequent cleaning processes can wear down equipment surfaces, leading to premature equipment failure and the need for costly replacements or repairs. |

| Safety Hazards | Scale build-up can create hazardous conditions, especially in acidulation reactors. For example, if heat transfer is impaired due to scale, there could be a risk of overheating, leading to pressure build-up and potentially hazardous conditions for plant personnel. |

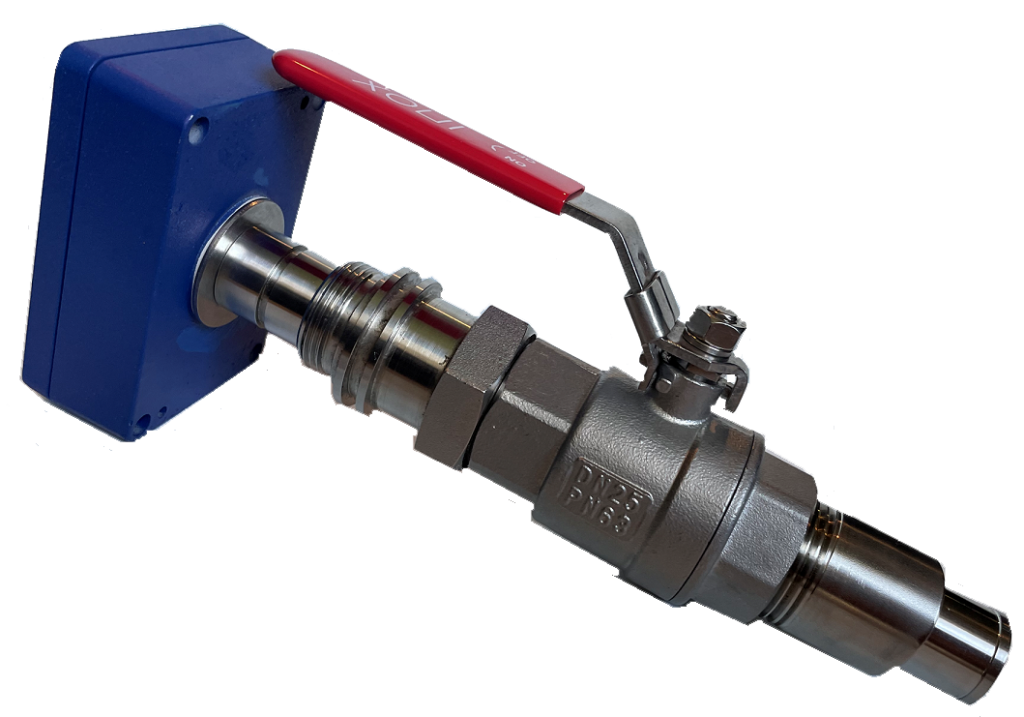

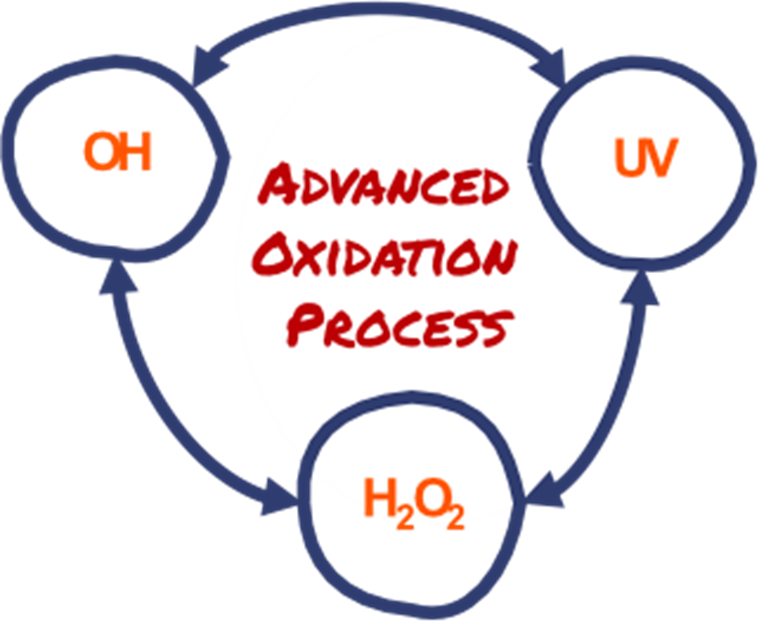

At WeHAP, we offer a ultrasonic scale prevention and removal systems to improve tall oil separation processes. The ZPD solution employs high-frequency sound waves to disrupt scale formation at a molecular level, ensuring that equipment remains free from build-up and operates at peak efficiency.This system uses sound to reduce fouling deposits on surfaces This action restores all efficiencies and reduces capacity limitations.

WeHAP will bring you the experts to guide you in your investigation of ultrasonic technology for your tall oil system.

For More Information: [email protected]

To set up conference call: [email protected]

0 Comments