Ultrasonic Scale Prevention System represents a leap forward in industrial scale management, combining technical innovation with operational efficiency and environmental responsibility. Embrace the future of scale prevention with WeHAP's ZPD solution – because at WeHAP, We Have A Plan. ZPD Ultrasonic Scale Prevention System stands out with its technical sophistication and efficiency-enhancing capabilities. This blog post discusses some of the technical aspects of the ZPD solution, shedding light on how it sets a new standard in scale management and operational excellence.

Ultrasonic Transducers: The Heart of the System

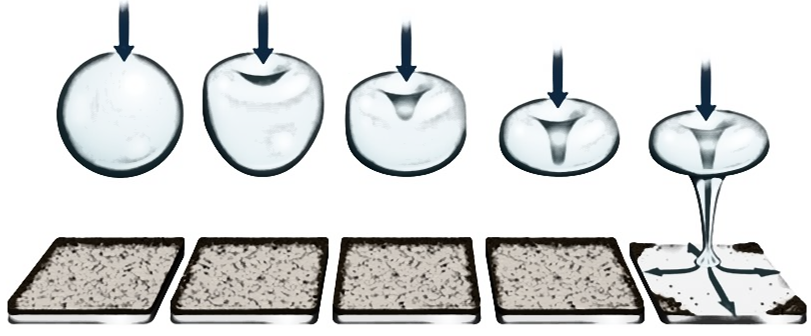

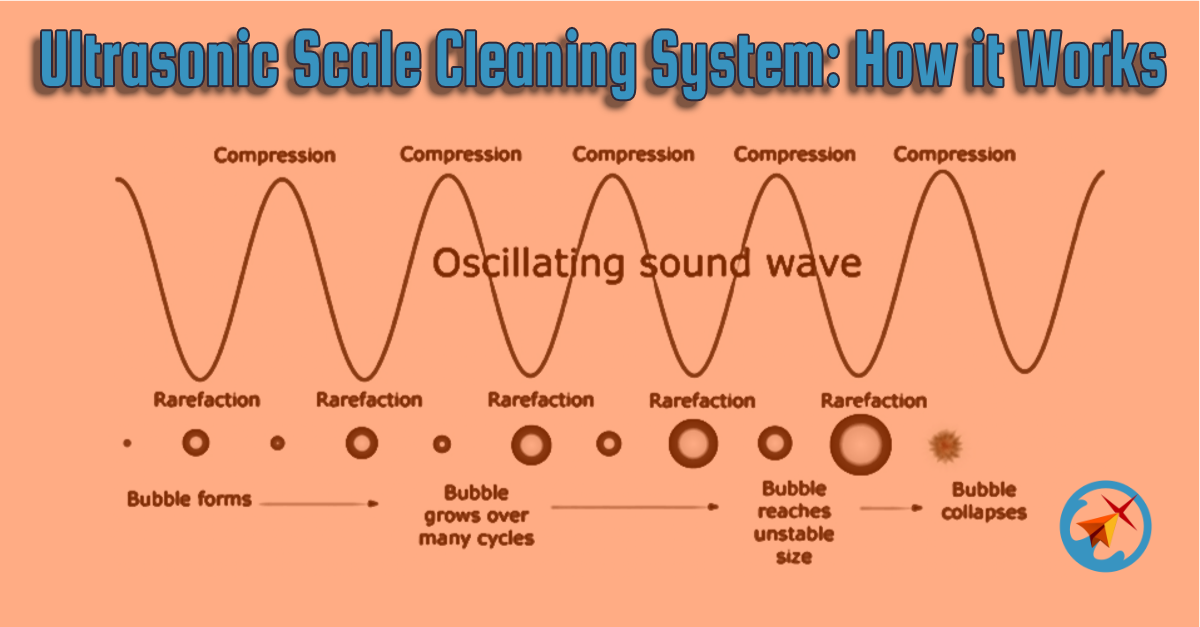

At the core of the ZPD solution are high-performance ultrasonic transducers, designed to emit sound waves at frequencies beyond human hearing. These transducers generate a cavitation effect in the liquid medium, creating microscopic bubbles that implode, producing powerful shockwaves. This process disrupts the typical scale formation cycle, preventing the accumulation of scale on equipment surfaces.

Software-Driven Control for Precision and Adaptability

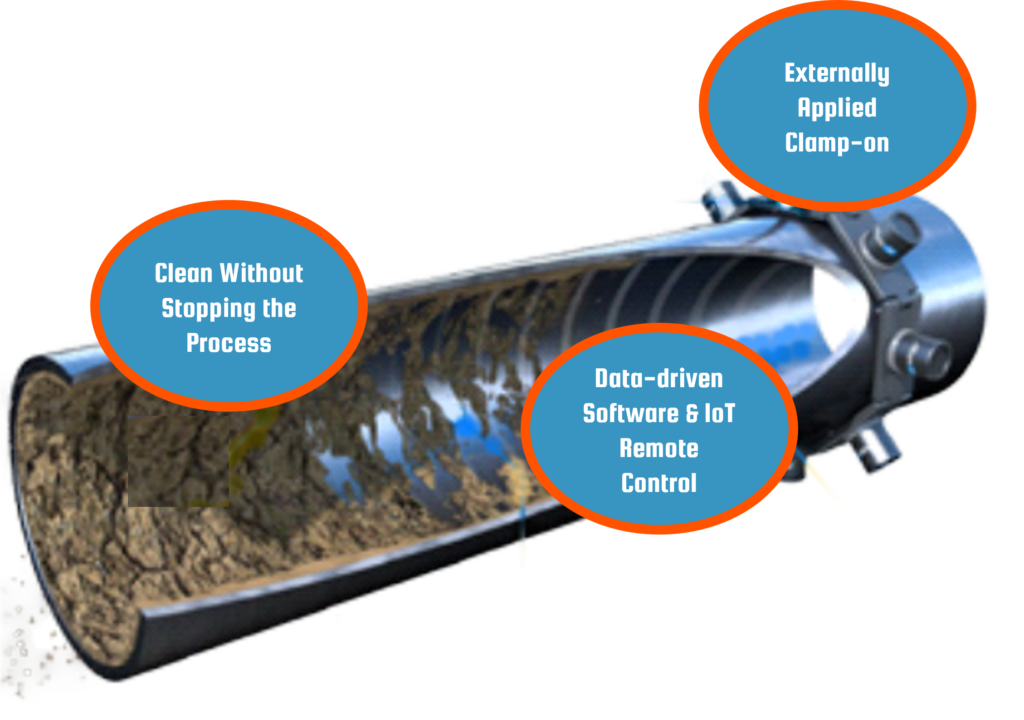

Complementing the transducers is an advanced software platform that controls the frequency, power, and duration of ultrasonic emissions. This software ensures that the ultrasonics are perfectly tuned to the specific conditions of the industrial process, maximizing efficiency and preventing scale without disrupting operations.

Real-Time Monitoring for Continuous Optimization

An integral part of the ZPD solution is its real-time monitoring capabilities. Sensors strategically placed throughout the system provide instant feedback on performance, allowing for dynamic adjustments and ensuring optimal scale prevention at all times.

Implementation: Tailored for Seamless Integration

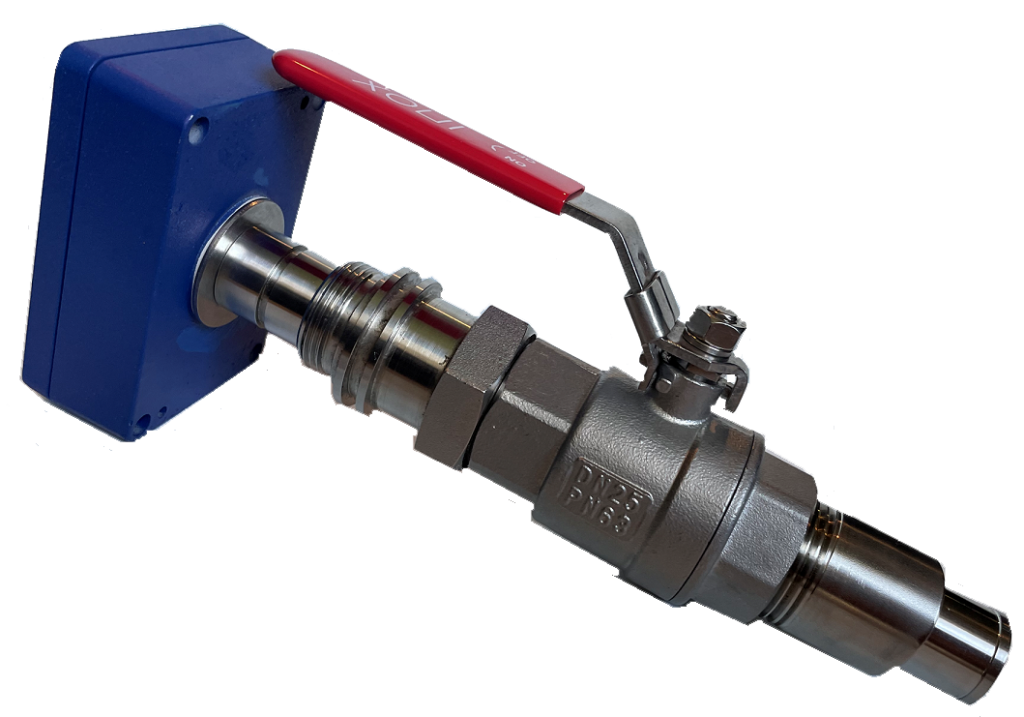

Implementing the ZPD solution involves a detailed analysis of the existing process flow, followed by the strategic placement of transducers and monitoring equipment. WeHAP's experts work closely with clients to ensure minimal disruption during installation, integrating ZPD into the process seamlessly.

Tangible Results: Beyond Scale Prevention

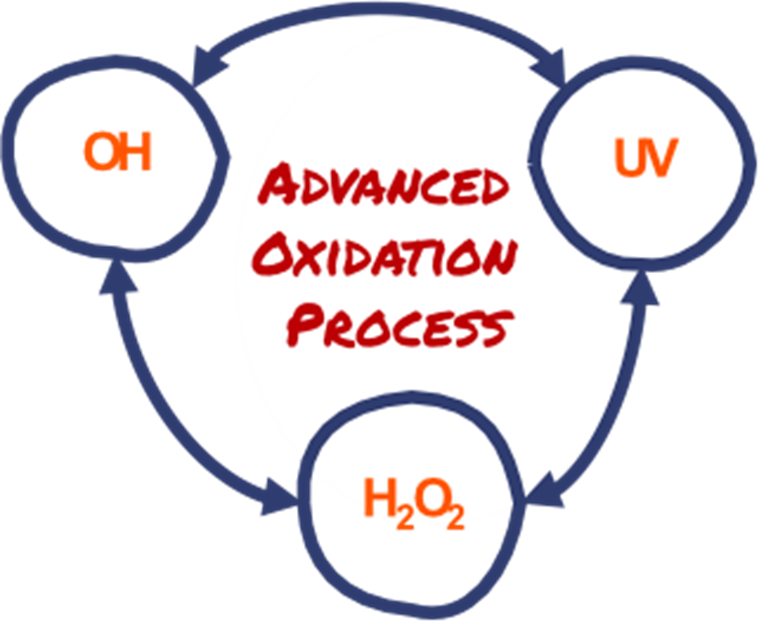

The impact of the ZPD solution extends far beyond mere scale prevention. By maintaining clean heat transfer surfaces, it significantly improves thermal efficiency, leading to substantial energy savings. Moreover, the reduced need for chemical scale inhibitors contributes to a more sustainable and environmentally friendly operation.

Financial Implications:

A Smart Investment Investing in the ZPD solution translates into direct financial benefits. The enhanced process efficiency and energy savings quickly offset the initial setup costs, while the prolonged lifespan of equipment due to reduced wear and tear further improves the return on investment.

Sanity Check!

Take a 27 minute Sanity Check to determine if you should investigate. We can go over our Feasibility Check process. We invite you to explore the technical sophistication of the ZPD Ultrasonic Scale Prevention System further. For more information, or to schedule a consultation with a subject matter expert, please reach out to [email protected] or request a meeting by emailing [email protected].

For More Information: [email protected]

To set up conference call: [email protected]

0 Comments