Imagine a tiny army of microscopic bubbles, armed with the power of high-frequency sound waves, diving into the nooks and crannies of your equipment. With a dramatic burst, they implode, unleashing a shockwave of cleaning power that knocks the daylights out of scale deposits clinging for dear life onto your pipes...and boosts Tall Oil Separation and Production Efficiency.

It's like having a microscopic Hulk in your cleaning closet, minus the green rage and torn pants.

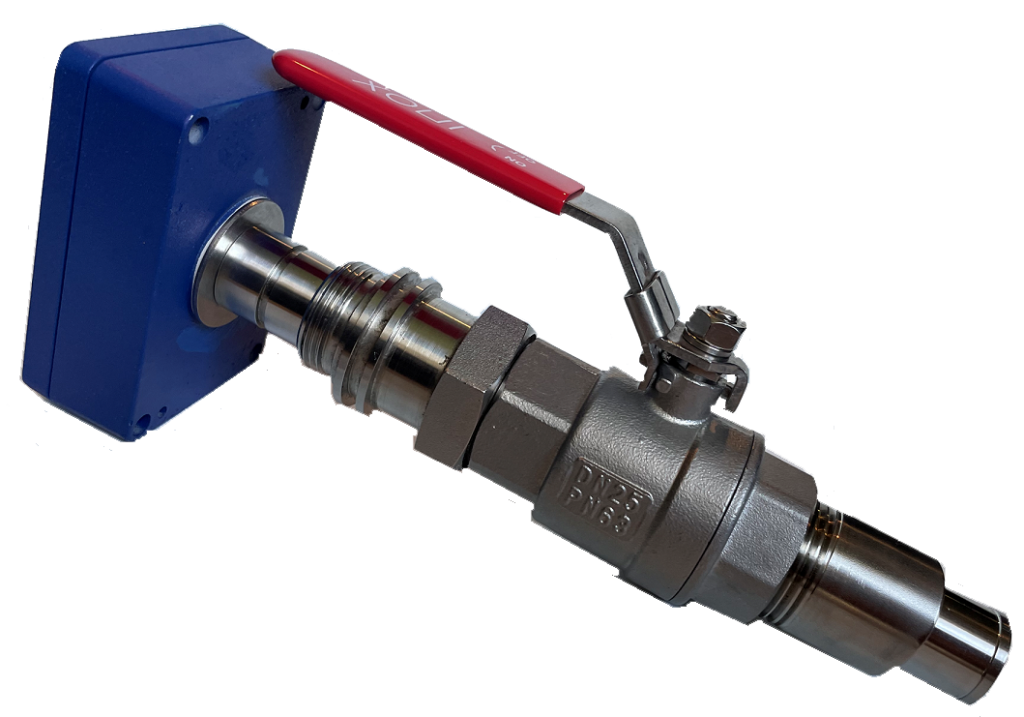

Traditionally, mechanical cleaning and chemical treatments have been the go-to methods for combating these issues. However, these can often be time-consuming, potentially hazardous, and less effective over time. The advent of ultrasonic scale and fouling cleaning systems has ushered in a new era of operational efficiency and prolonged production uptime.

Uptime... The Holy Grail

Now, let's talk uptime – the Holy Grail of production. Employing ultrasonic cleaning isn't just about making your equipment sparkle; it's about keeping the show running without a hitch. By banishing the clingy scale and fouling your tall oil process lines are cleaner longer. This means fewer shutdowns for maintenance, less energy spent heating up excess baggage, and more time doing what your plant does best – churning out high revenue tall oil byproduct.

Squeezing out More Production Days

The application of ultrasonic cleaning in tall oil processing lines offers several advantages. Firstly, it can be conducted in situ, meaning the cleaning process can occur without dismantling the equipment, significantly reducing downtime. Additionally, ultrasonic cleaning provides a uniform cleaning effect, reaching even the most inaccessible parts of the processing lines, ensuring a thorough cleaning that traditional methods might miss.

By maintaining cleaner lines, tall oil operations can experience more stable flow rates and temperature control, crucial for maintaining product quality and process efficiency. Ultrasonic scale prevention and removal can adapt to various operational conditions, making them a versatile solution for different stages of the tall oil production process.

Yes... You're Thinking Outside the Box.

Sure, ultrasonic has been around but still... an army of tiny bubbles might still be scary to some. A forward thinker in a tall oil situation, adopting ultrasonic scale prevention and removal system is going to stand out. By embracing this innovative technology, processors can not only ensure cleaner lines but also contribute to a more sustainable and efficient production environment.

For More Information: [email protected]

To set up conference call: [email protected]

0 Comments