What are the operational advantages and economic impacts of having continuous ash content measurements various papermaking stages and in monitoring effluent?

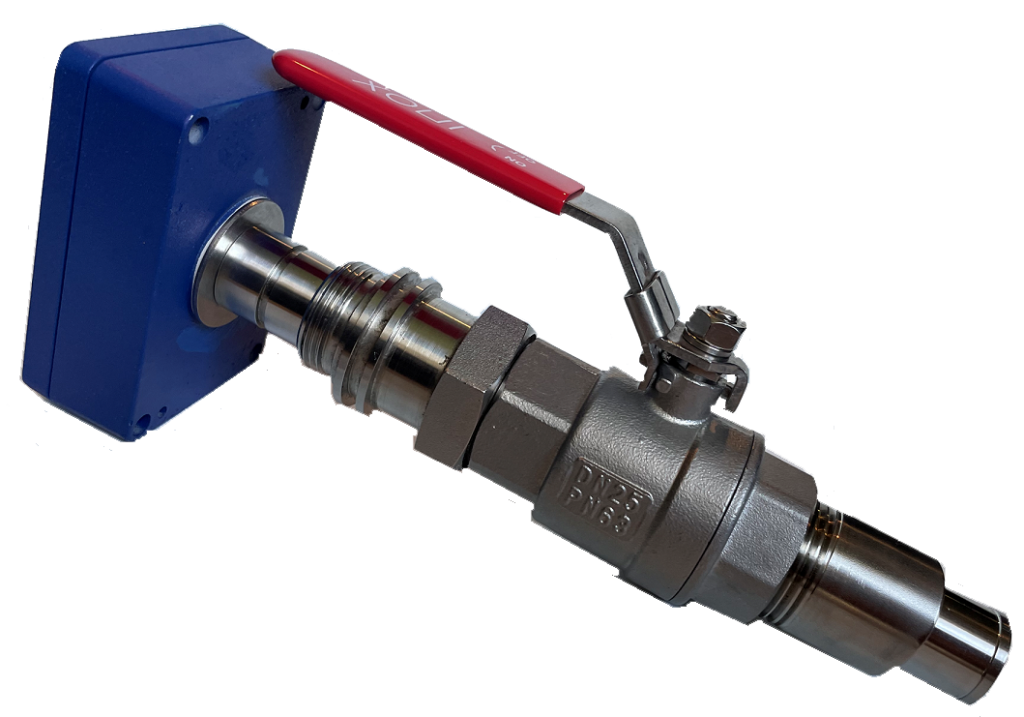

The ProEye 100 configured for continuous Ash Content measurement provides the data necessary for decision-making without disrupting the ongoing process. Rather than waiting on lab analysis to make control adjustments, use the lab analysis to confirm your ProEye 100 readings and make larger control moves if appropriate

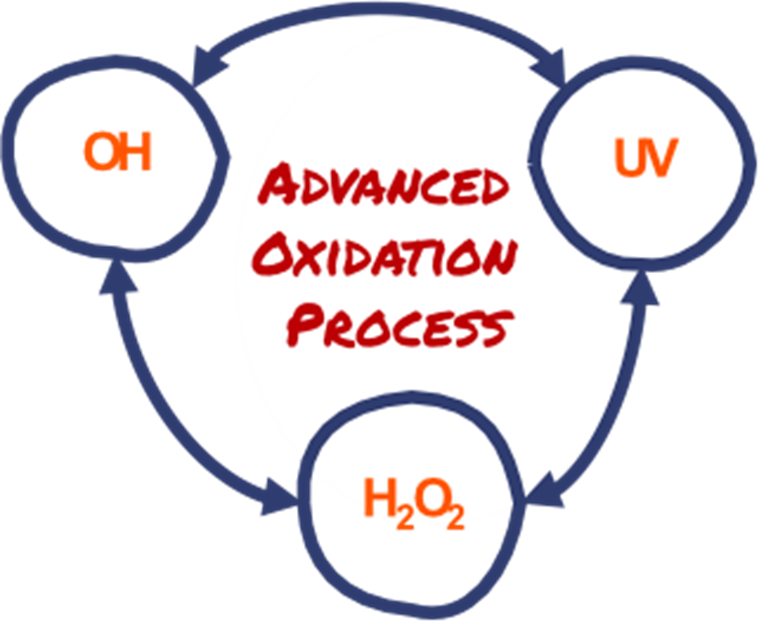

Continuous measurement of Ash Content is beneficial after cooking and washing take place, at the outlet of the bleach plants, and many spots within the stock prep area. Monitoring Ash Content in the effluent stream provides indications of washing efficiency, wastewater treatment failures, and fiber loss.

Operational Advantages and Economic Impacts

| Benefit | Operational Advantage | Economic Impact |

| Real-Time Adjustment | Better data, finer adjustments. Smaller, frequent changes lead efficient operation and better quality control | Application of minimum amount of chemical, energy and material needed for desired quality |

| Product Quality | Ensure that the bleaching chemicals and other inorganic substances have been adequately removed resulting better influence on final properties such as printability, strength and opacity | Reduce rework and and product rejection Higher yield of acceptable product |

| Reduced Waste | Maintaining ash content in desired range | Minimized waste equates eliminating unnecessary cost |

| Optimizing Resources | More advanced control strategy. Optimization reduces the need for subsequent downstream adjustments saving money in raw materials, energy, bleaching agents and other process chemicals | Lower material Cost Per Ton |

| Equipment Maintenance | Predictability in the process extends equipment life time | Lower manpower costs and unplanned outages |

| Performance Indication | Identify abnormal situations from effluent monitoring such as insufficient washing of the pulp or a failure in the wastewater treatment system | Shortening or avoiding abnormal situations saves money and stress |

| Early warning | Effective washing processes help meet regulations. Early detection and improved alarm design to prevent or mitigate environmental issues | Fine or clean-up cost avoidance |

For control room operators and process control engineers, continuous ash content measurement provides a wealthier set of data for improving process control strategies. It can be used to implement advanced control loops and allows for the development of sophisticated models for predictive control and optimization. These benefits combined lead to a more stable, efficient, and cost-effective operation

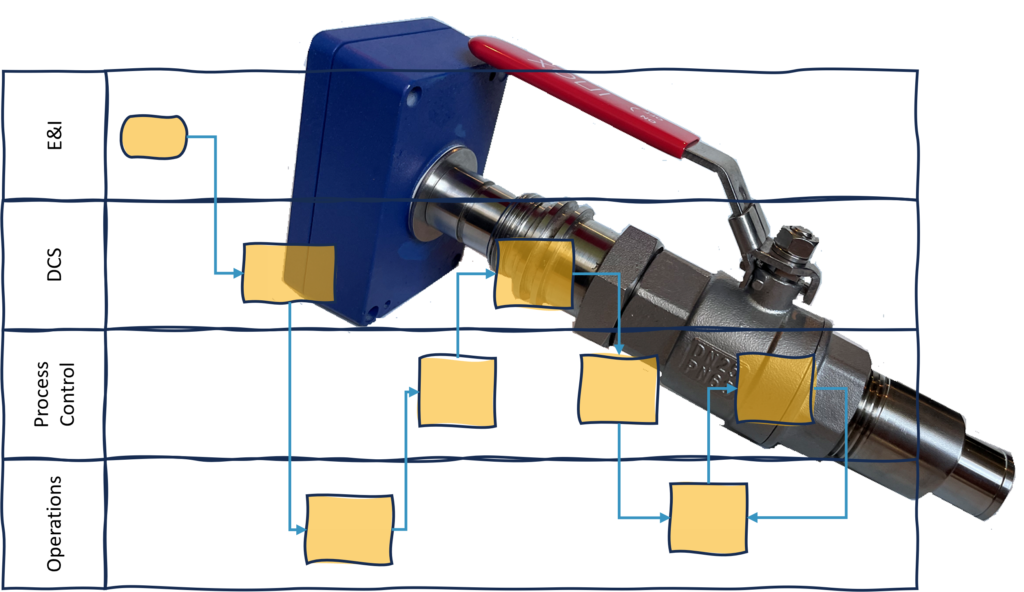

How do you get a Conmark Pro-Eye 100 into your operation?

- Consult with a WeHAP engineer

- Fill out a process description form

- Take some pictures

- Consider the WeHAP location recommendation

- Install an insertion point

- Install the transmitter

- Sample (you do it) and calibrate (we do it)

- Connect to your control system

- Design your alarms

Connect

For More Information: [email protected]

To set up conference call: [email protected]

Want to get specs or talk pricing and/or installation? Contact [email protected]

0 Comments