Equipment Hygiene

Technologies with the ultimate goal of keeping industrial processes running with the highest possible uptime. Shutting down operations to manually open and clean process equipment is a costly practice that has until now always been accepted as a cost of doing business. We offer solutions The solution can be installed and used without stopping your production lines and without making any changes to the equipment.

-

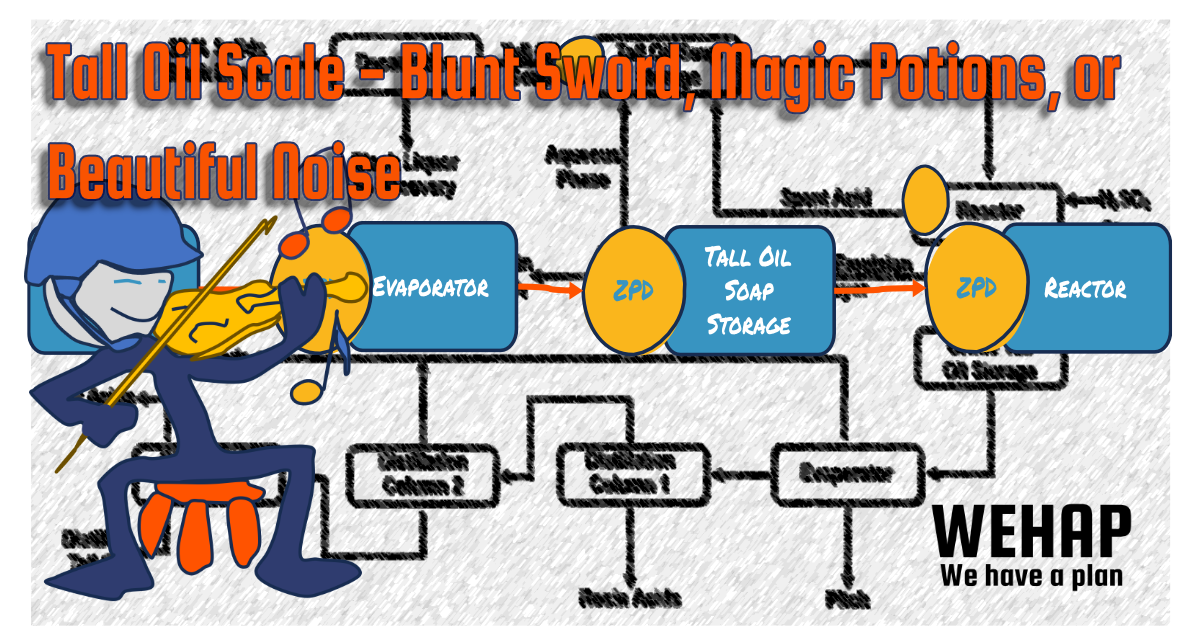

Tall Oil Separation Efficiency – Cleaning with a Blunt Sword, Potions with Side Effects or with Beautiful Noise

-

Tiny Army of Bubbles: More UpTime at the Tall Oil Plant

Unlock the potential of ultrasonic cleaning in tall oil production with WeHAP's revolutionary solution. Experience unparalleled efficiency and upti...

-

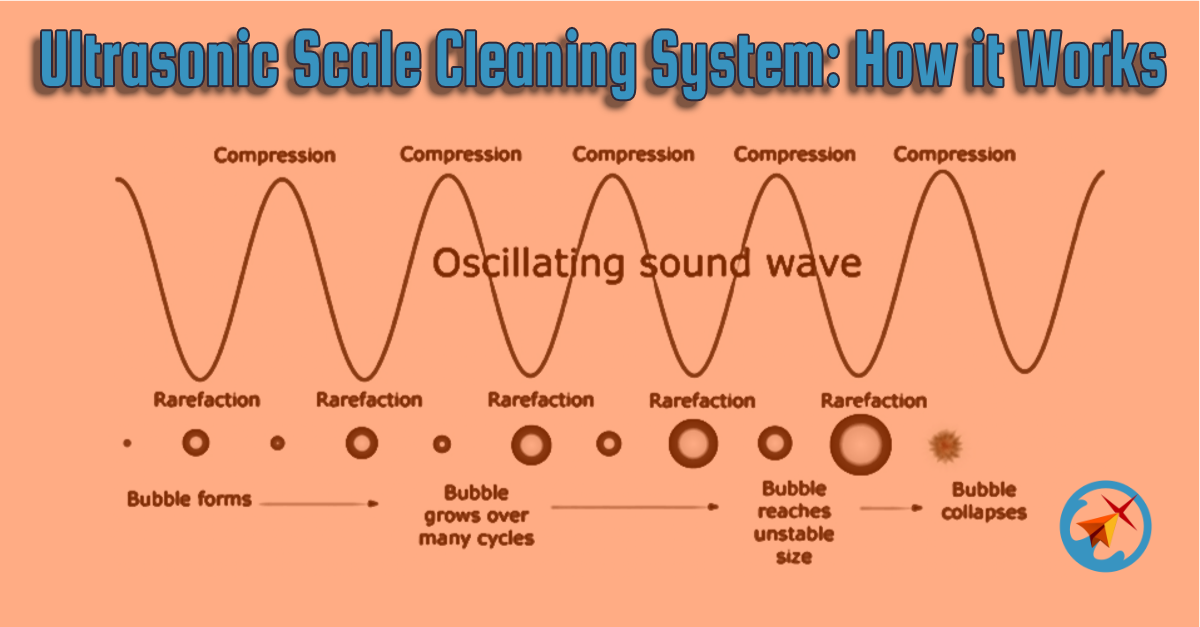

Ultrasonic Scale Cleaning System: How it works

Explore the technical depth of WeHAP's ZPD Ultrasonic Scale Prevention System, a groundbreaking solution that revolutionizes scale management throu...

-

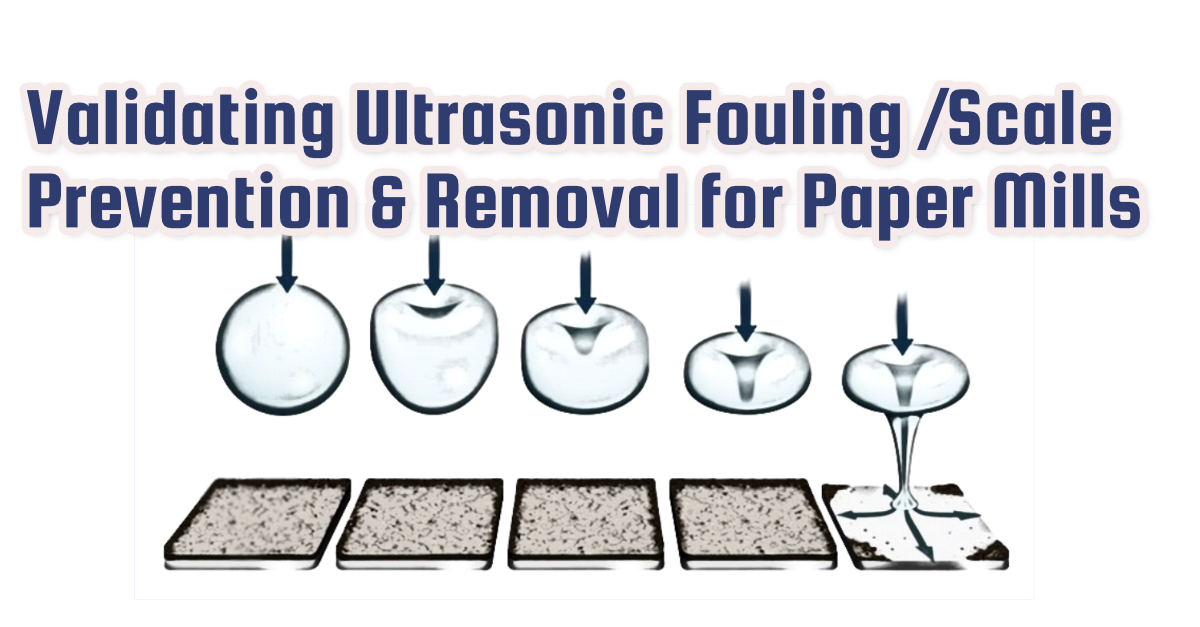

How Can I Be Certain of ZPD’s Impact on My Operation?

-

Hard, Crusty Layers Messing Up My Tall Oil Plant!

-

Supercharge Your Evaporator Plant: The Magic of Merging Anti-Scalants with Ultrasonic Fouling Prevention

Combining anti-scalants with ultrasonic fouling prevention is revolutionizing the world of evaporators. This powerful duo offers operational and fi...

-

Excessive, disruptive fouling does not have to be the cost of doing business