Paper Satron VCF – Real-time Freeness Values, No Time-Outs

Real-time Freeness Values, No Time-Outs More precise control over the refining process, results in less waste, higher yield and reduced production costs. Easier said than done. The Satron Lumina VCF provides real-time data on the pulp’s degree of refining to...

You don’t need Tarot cards!

You don’t need Tarot cards to figure out when dairy product is going down the drain You don’t need a card reading to figure out when product is going down the drain. You need rapid notification for Product Loss and an early warning on peak COD or an abnormal...

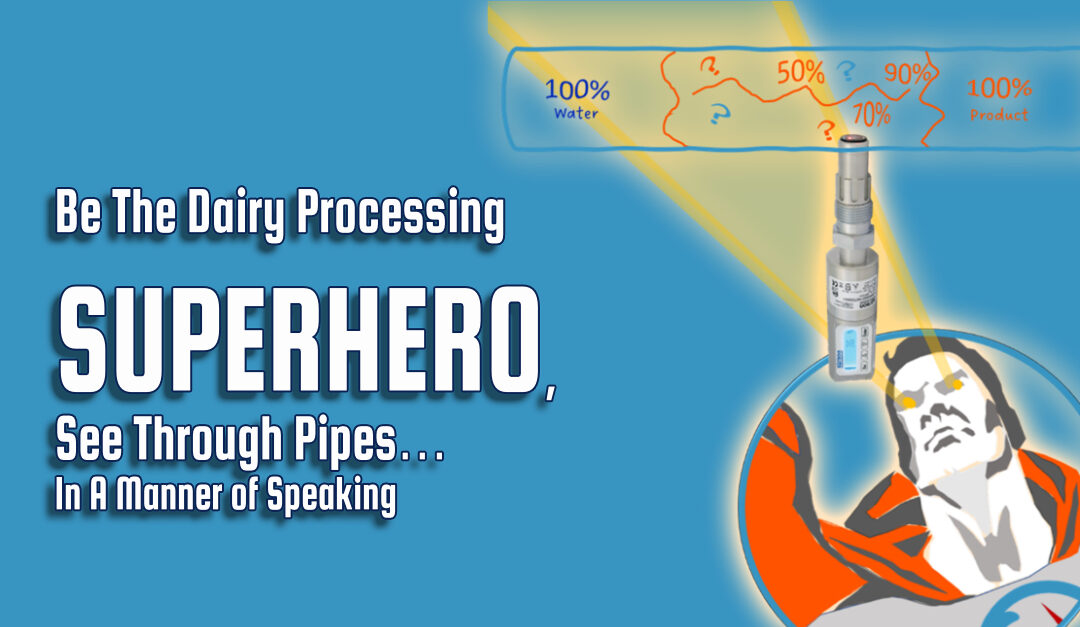

Be The Dairy Processing Superhero, See Through Pipes…In A Manner of Speaking

So… you are not Superhero, TODAY. But who knows, maybe tomorrow… you can SEE THROUGH PIPES!Avoiding regulatory fines, municipal overage fees, saving aquatic life are all part of a processing plant engineer and technician’s day.With the Satron VO you give operators...

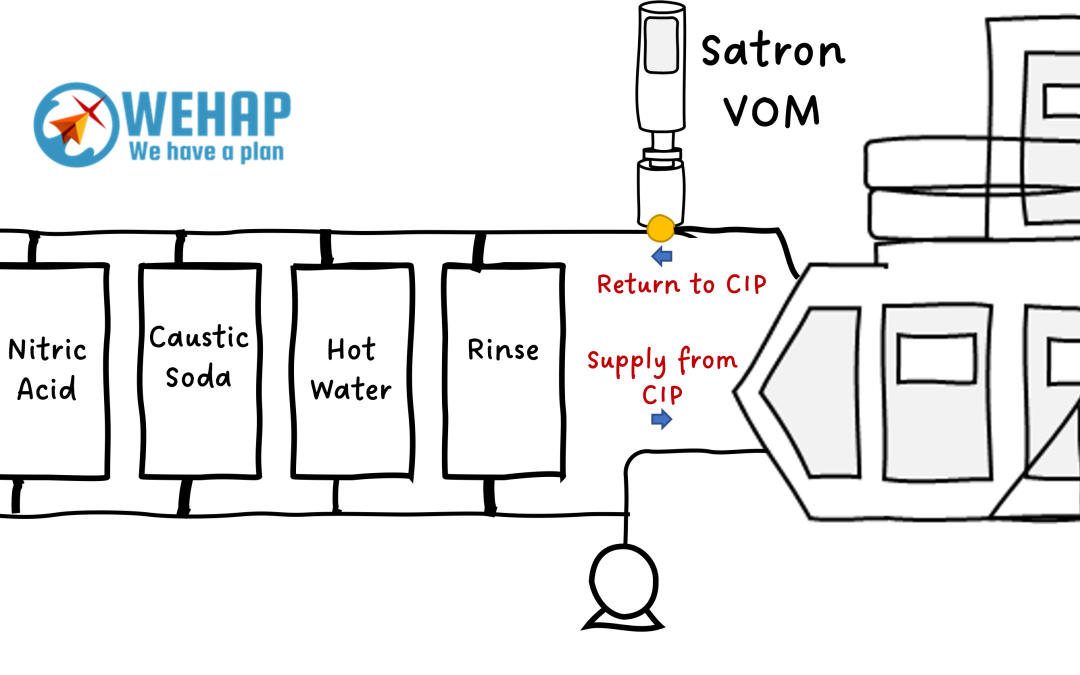

What If You Could Get More Filling Machine Availability Each Week?

We’re suggesting a reduction cleaning time with real-time turbidity measurement where a conductivity measurement is not enough.

Take yogurt process for example. With the VO sensor you can safely shorten the filling machine, for example pre-rinse cycle by reducing configured safety margins or eliminating unnecessary human intervention, leading to overall reduced CIP time.