by David Garcia | Mar 28, 2024

Unlock the potential of ultrasonic cleaning in tall oil production with WeHAP’s revolutionary solution. Experience unparalleled efficiency and uptime as microscopic bubbles tackle stubborn scale deposits. Dive into the future of industrial cleaning, where downtime is minimized, and productivity soars

by David Garcia | Mar 27, 2024

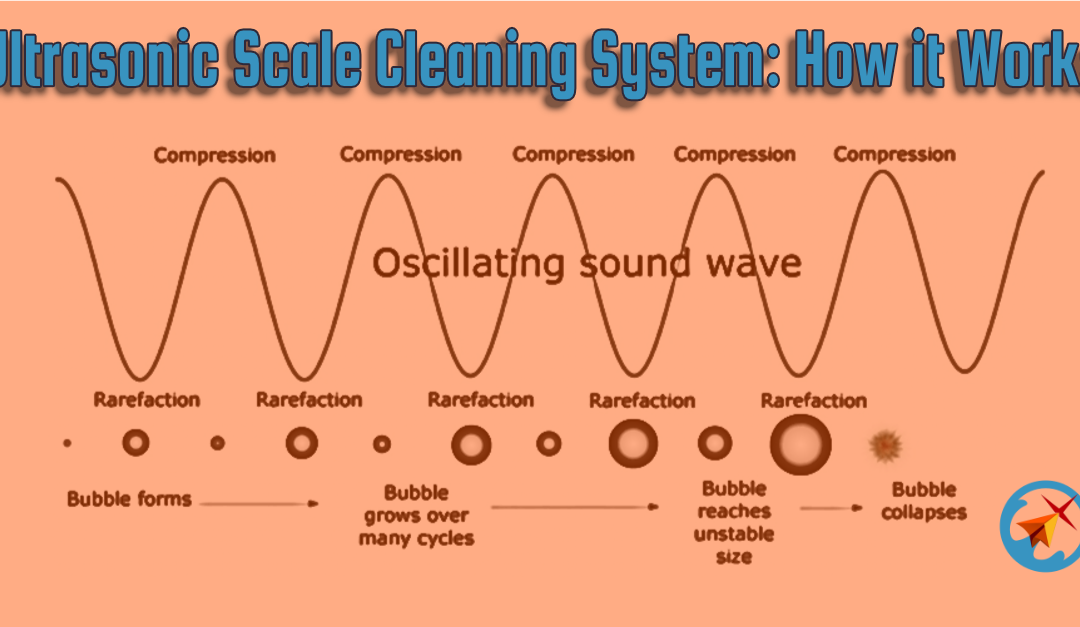

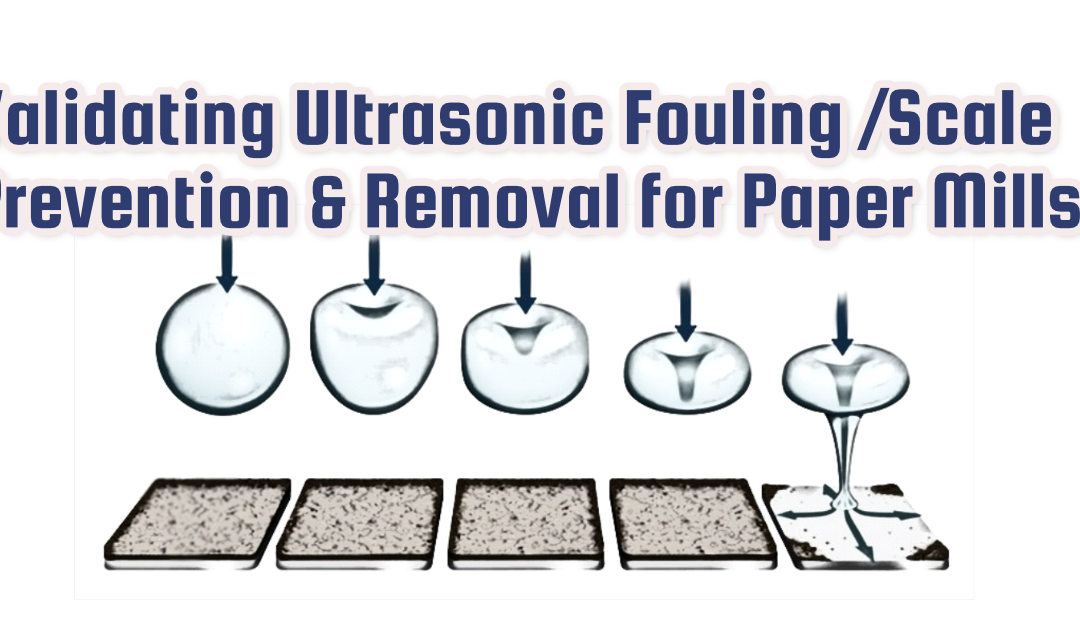

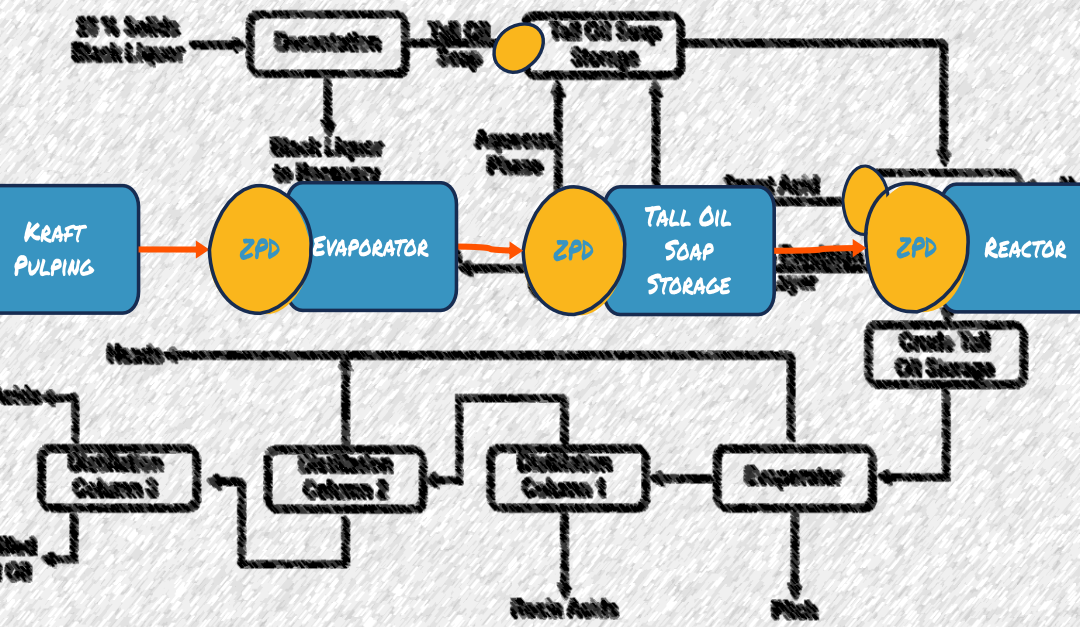

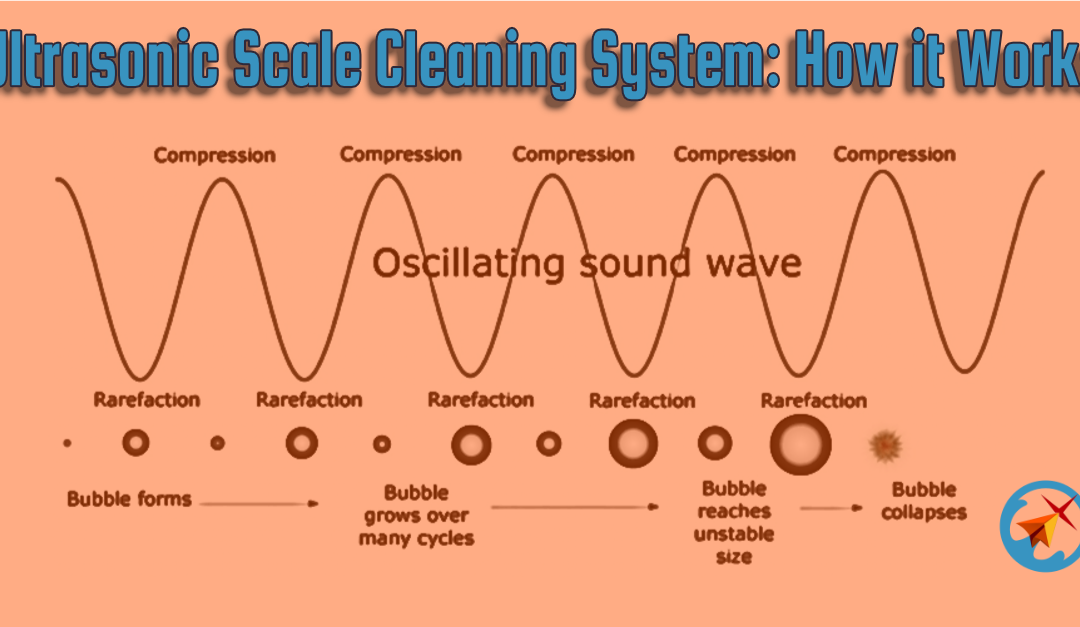

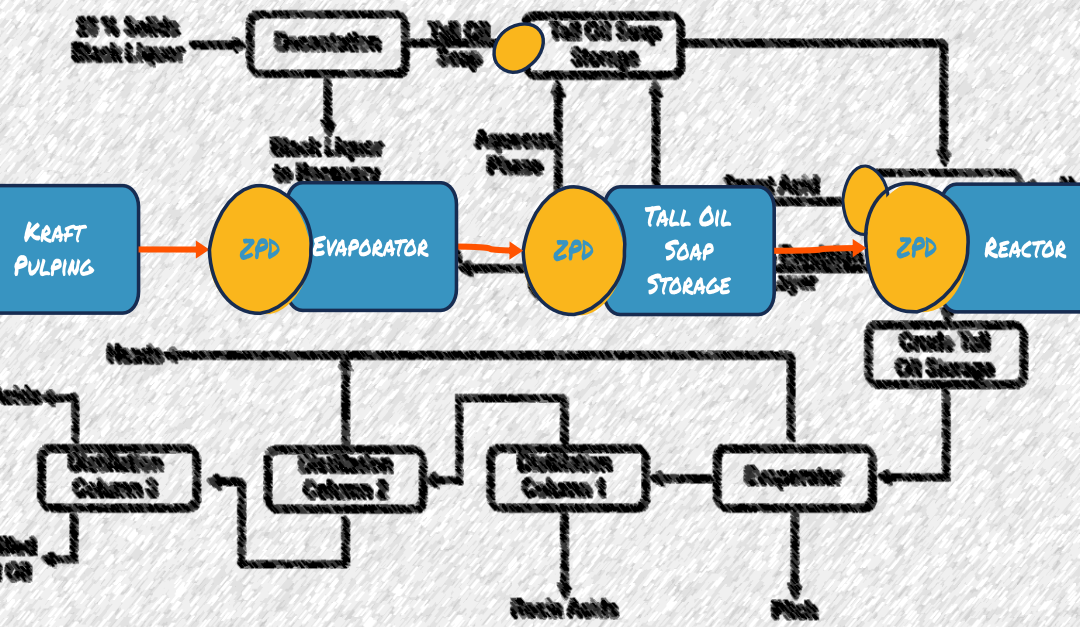

Explore the technical depth of WeHAP’s ZPD Ultrasonic Scale Prevention System, a groundbreaking solution that revolutionizes scale management through ultrasonic technology. Discover how the precise application of ultrasonics inhibits scale formation, enhances process efficiency, and propels financial savings. Learn about the specialized components and implementation strategies that make ZPD an industry benchmark in combating scale-related challenges.

by David Garcia | Mar 26, 2024

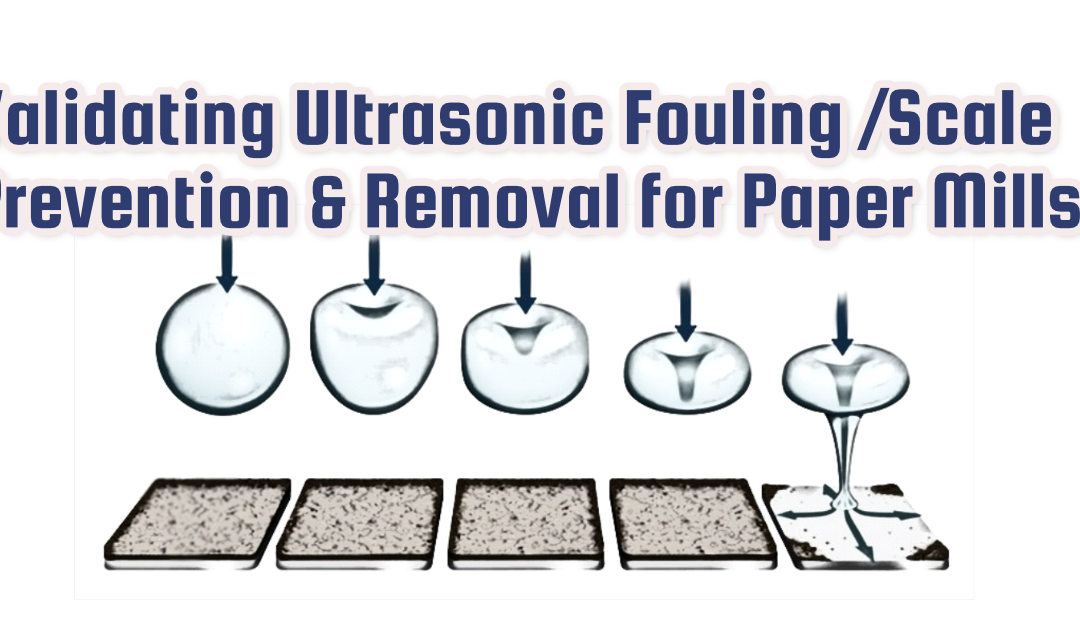

So what is this a groundbreaking technology is going to do for me? This blog delves into the process you and ultrasonic technology experts will use to determine the feasibility and return on investment (ROI) by implementing the state-of-the-art Ultrasonic Scale...

by David Garcia | Mar 8, 2024

Hard, crusty layers that cling tenaciously in the tall oil plant are a pain in the butt. Just like that kettle used to boil hard water for a long time without cleaning; the white, chalky substance that forms on the inside is similar to the scale buildup in the tall...

by David Garcia | Feb 1, 2024

Discover the unmatched capabilities of the ProEye CS Consistency Transmitter in pulp and paper production. With its superior accuracy, minimal process interference, and advanced features, it stands out as the optimal choice. Learn how ProEye CS ensures consistent quality and operational efficiency, solidifying its status as a leader in the industry.