The Future of Pulp Bleaching

In fine paper manufacturing, quality is non-negotiable—but margins are. As mills navigate rising chemical costs, tightening environmental regulations, and pressure to increase operational efficiency, a critical question arises:

Can we make our bleaching process more cost-effective without compromising brightness or quality?

For many mills, the answer is yes—with enzymatic bleaching.

The Role of Enzymatic Bleaching

Enzymatic bleaching serves as a booster within the standard Elemental Chlorine-Free (ECF) or Totally Chlorine-Free (TCF) bleaching sequence. Enzymes like thermostable xylanase—such as that found in Optimase CX 200L—break down the xylan network in pulp fibers, exposing lignin that would otherwise require higher doses of chlorine dioxide or peroxide to remove.

By improving lignin accessibility, enzymatic treatment enables mills to use less of their most expensive bleaching chemicals, while still achieving high brightness levels expected of fine papers.

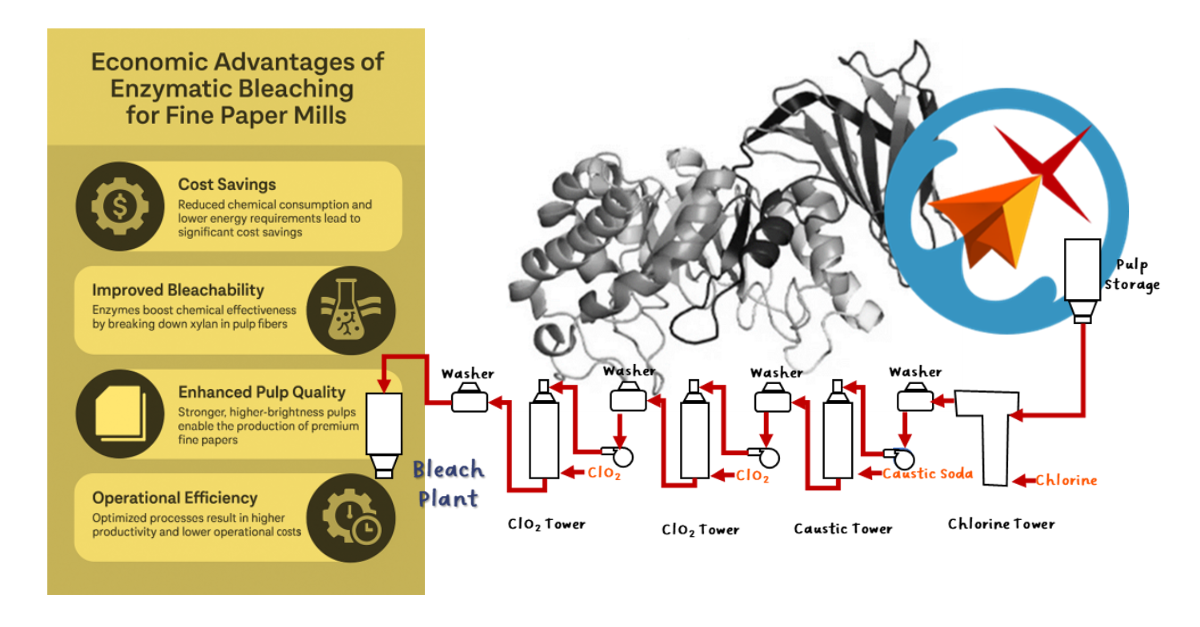

Economic Advantages for Fine Paper Mills

Reduce Chlorine Dioxide Usage

Chlorine dioxide is effective—but costly. Enzymatic pre-treatment has been shown to cut chlorine dioxide consumption by up to 25–30%, resulting in immediate savings on one of the most expensive parts of the bleaching sequence.

Lower Chemical Oxygen Demand (COD) & AOX

Reduced COD and AOX output can minimize downstream wastewater treatment costs and help mills avoid fines or surcharges. These reductions also support smoother permitting and compliance processes.

Maintain or Improve Brightness at Lower Cost

By making lignin more accessible early in the process, enzymes allow mills to achieve target brightness with fewer chemical inputs. In chlorine-limited mills, this can even enable higher throughput or reduced batch times, improving production economics without capital investment.

Enhance Fiber Utilization

Enzymatic treatment is gentler on fibers compared to aggressive chemical sequences, which can lead to fewer fiber losses and better paper strength properties, particularly valuable for high-performance fine papers.

Flexibility Without Capital Expense

Incorporating enzymatic bleaching typically requires minimal to no hardware changes. The enzyme is dosed as part of the existing bleaching sequence, providing a low-barrier, high-return process upgrade.

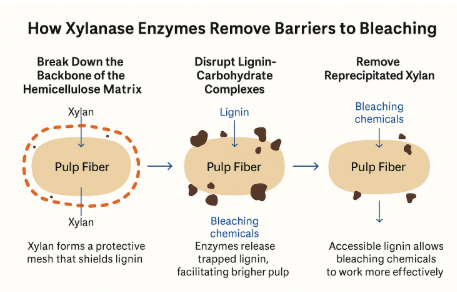

How Bleaching Enzymes Work

Bleaching enzymes target xylan, a key hemicellulose in wood fibers. By depolymerizing xylan, the enzymes:

- Remove barriers that prevent chemical penetration

- Break down the backbone of the Hemicellulose matrix

- Disrupt Lignin-Carbohydrate Complexes

- Remove reprecipitated Xylan; "resurfaced xylan" blocks bleaching chemicals

- Reduce absorption of bleaching chemicals; Xylan -rich areas can deplete chemicals before they reach lignin

- Enable easier lignin extraction in subsequent bleaching stages

- Lower Chemical Use: Reduces chlorine dioxide and peroxide needed in later bleaching stages.

- Higher Brightness Potential: Achieves target brightness with less chemical or boosts ceiling brightness.

- Reduced Environmental Load: Minimizes AOX, COD, and effluent treatment burden

- Preserved Fiber Strength: Avoids fiber damage from over-bleaching, improving paper quality.

- Faster Reactions: Improves chemical penetration, reducing retention time and energy use.

- Capex Deferral: Increases system efficiency, delaying need for equipment upgrades.

This enzymatic pretreatment is not a standalone bleaching step, but a complementary process that amplifies the efficiency of traditional bleaching chemicals like hydrogen peroxide, chlorine dioxide, and ozone.

The Future of Sustainable Bleaching

The integration of bleaching enzymes is not just an optimization—it’s a bold step toward an entirely new kind of pulp mill. A mill where sustainability and efficiency are no longer at odds. A mill where chemical use is minimized, costs are lower, and environmental compliance is easily achieved.

Engineers who embrace enzyme-based bleaching are not just adopting a new tool; they are building a cleaner, more sustainable industry from the ground up. Operational excellence and environmental responsibility are no longer opposing forces, but powerful allies in the pursuit of progress.

The future of pulp bleaching isn’t waiting to be discovered—it is being built by those ready to lead the charge.

Book Your Trial Today

Discover the power of bleaching enzymes through a customized lab or machine trial tailored to your mill’s needs. Whether you're optimizing an existing process or exploring new solutions, we will work with you to develop a tailored trial plan.

We will assist you on-site or remotely, allowing you to test the enzymes under real mill conditions with your materials.Our expert team will help you assess chemical reductions, enzyme performance, and pulp quality enhancements in a risk-free, controlled setting.

Join us in shaping a smarter, more sustainable approach to pulp bleaching. Together, we’ll craft a plan that aligns with your operational objectives and investment strategy.

Book your trial today!

Next Step to discuss a Lab or Machine Trial

Technical Data Sheet? Material Safety Data Sheet? Brochures? For More Information: [email protected]

Process Discussion? Schedule a Trial? To set up conference call: [email protected]

0 Comments