Enzymes as Game-Changers: For Engineers Who Build the Future of Pulp Bleaching

Engineers Are Building a New Era of Pulp Bleaching

Engineers are not bound by the constraints of the past—they build what has never been before. For decades, the industry has relied on chlorine-based chemicals, creating a legacy of environmental challenges like Adsorbable Organic Halides (AOX). Now, pulp and paper mills stand at a critical crossroads, and engineers have the power to drive change.

Bleaching enzymes, particularly xylanases, offer a smarter alternative that increases efficiency while drastically reducing environmental impact. This is more than just an evolution—it’s an engineered revolution in pulp bleaching.

The Role of Enzymatic Bleaching

Bleaching enzymes serve as a "boosting" step in the bleaching sequence. By breaking down the xylan network in pulp fibers, these enzymes expose trapped lignin, allowing chemical bleaching agents to work more effectively. This process reduces reliance on chlorine compounds, lowering AOX formation and overall chemical use while maintaining high-quality pulp.

Key Benefits of Bleaching Enzymes

1. Environmental Sustainability

Reduces AOX discharge by up to 25% and Chemical Oxygen Demand (COD) by up to 85%

Helps mills comply with stringent environmental regulations and sustainability goals

2. Improved Efficiency

Lowers chemical consumption by 10–30% in ECF (Elemental Chlorine-Free) and TCF (Totally Chlorine-Free) processes

Enhances brightness by up to 2.1 ISO units, enabling the production of higher-grade pulps

3. Cost Savings

Reduces the need for expensive bleaching agents like chlorine dioxide and hydrogen peroxide

Lowers energy consumption by optimizing chemical reactions and reducing mechanical demands

4. Superior Pulp Quality

Maintains or improves fiber strength while reducing brightness reversion

Ensures better bleachability without compromising the structural integrity of pulp fibers

5. Adaptability Across Mills

Effective for hardwood, softwood, and non-wood pulps (e.g., wheat straw, rice straw, jute)

Operates efficiently across a wide pH and temperature range, requiring minimal process modifications

How Bleaching Enzymes Work

Bleaching enzymes target xylan, a key hemicellulose in wood fibers. By depolymerizing xylan, the enzymes:

Remove barriers that prevent chemical penetration

Enable easier lignin extraction in subsequent bleaching stages

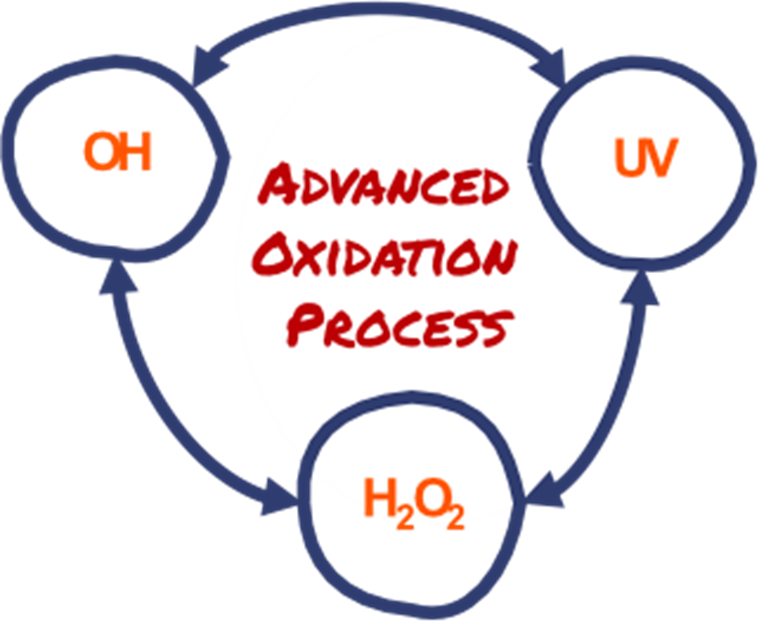

This enzymatic pretreatment is not a standalone bleaching step, but a complementary process that amplifies the efficiency of traditional bleaching chemicals like hydrogen peroxide, chlorine dioxide, and ozone.

The Future of Sustainable Bleaching

The integration of bleaching enzymes is not just an optimization—it’s a bold step toward an entirely new kind of pulp mill. A mill where sustainability and efficiency are no longer at odds. A mill where chemical use is minimized, costs are lower, and environmental compliance is easily achieved.

Engineers who embrace enzyme-based bleaching are not just adopting a new tool; they are building a cleaner, more sustainable industry from the ground up. Operational excellence and environmental responsibility are no longer opposing forces, but powerful allies in the pursuit of progress.

The future of pulp bleaching isn’t waiting to be discovered—it is being built by those ready to lead the charge.

Book Your Trial Today

Discover the power of bleaching enzymes through a customized trial tailored to your mill’s needs. Whether you're optimizing an existing process or exploring new solutions, we will work with you to develop a tailored trial plan.

We will assist you on-site or remotely, allowing you to test the enzymes under real mill conditions with your materials.Our expert team will help you assess chemical reductions, enzyme performance, and pulp quality enhancements in a risk-free, controlled setting.

Join us in shaping a smarter, more sustainable approach to pulp bleaching. Together, we’ll craft a plan that aligns with your operational objectives and investment strategy.

Book your trial today!

Next Step to discuss your Stock Prep Vision

Technical Data Sheet? Material Safety Data Sheet? Brochures? For More Information: [email protected]

Process Discussion? Schedule a Trial? To set up conference call: [email protected]

0 Comments