Real-time Freeness Values, No Time-Outs

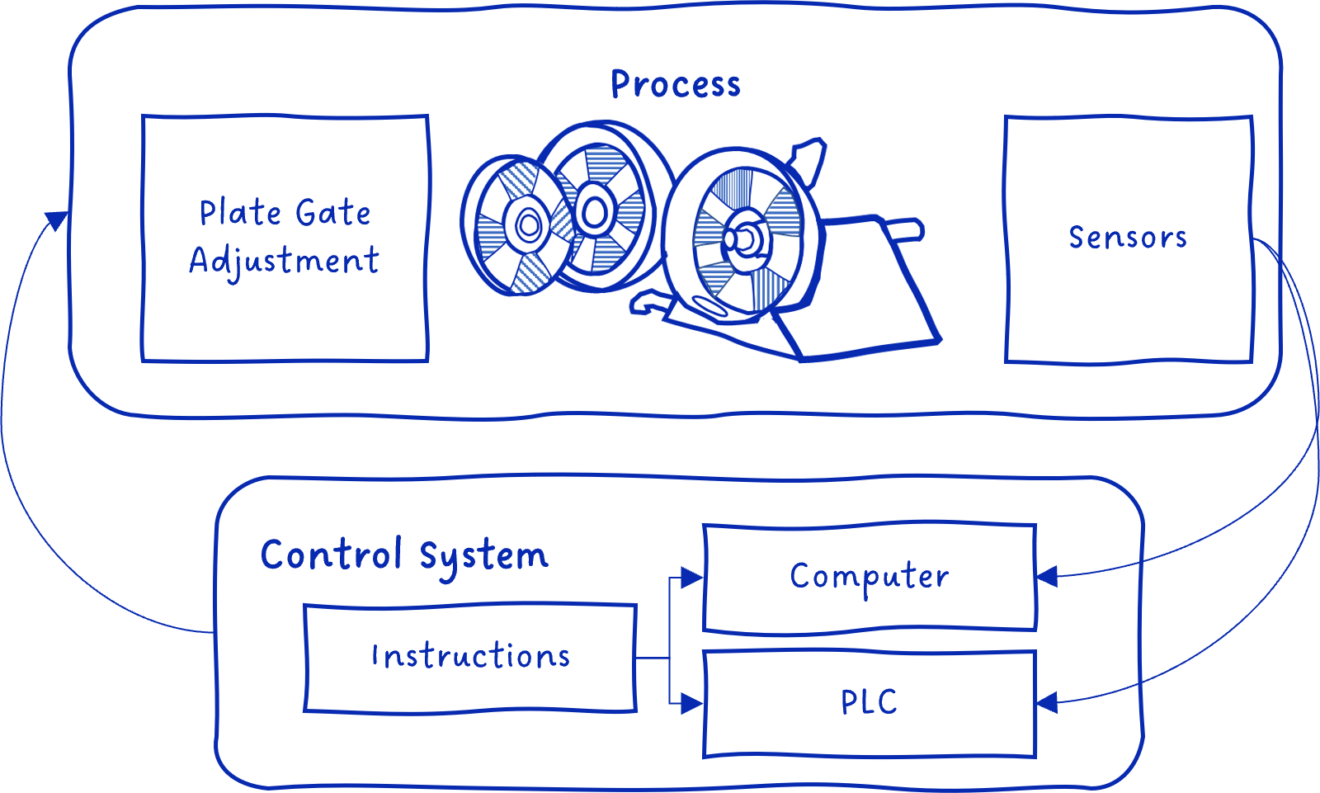

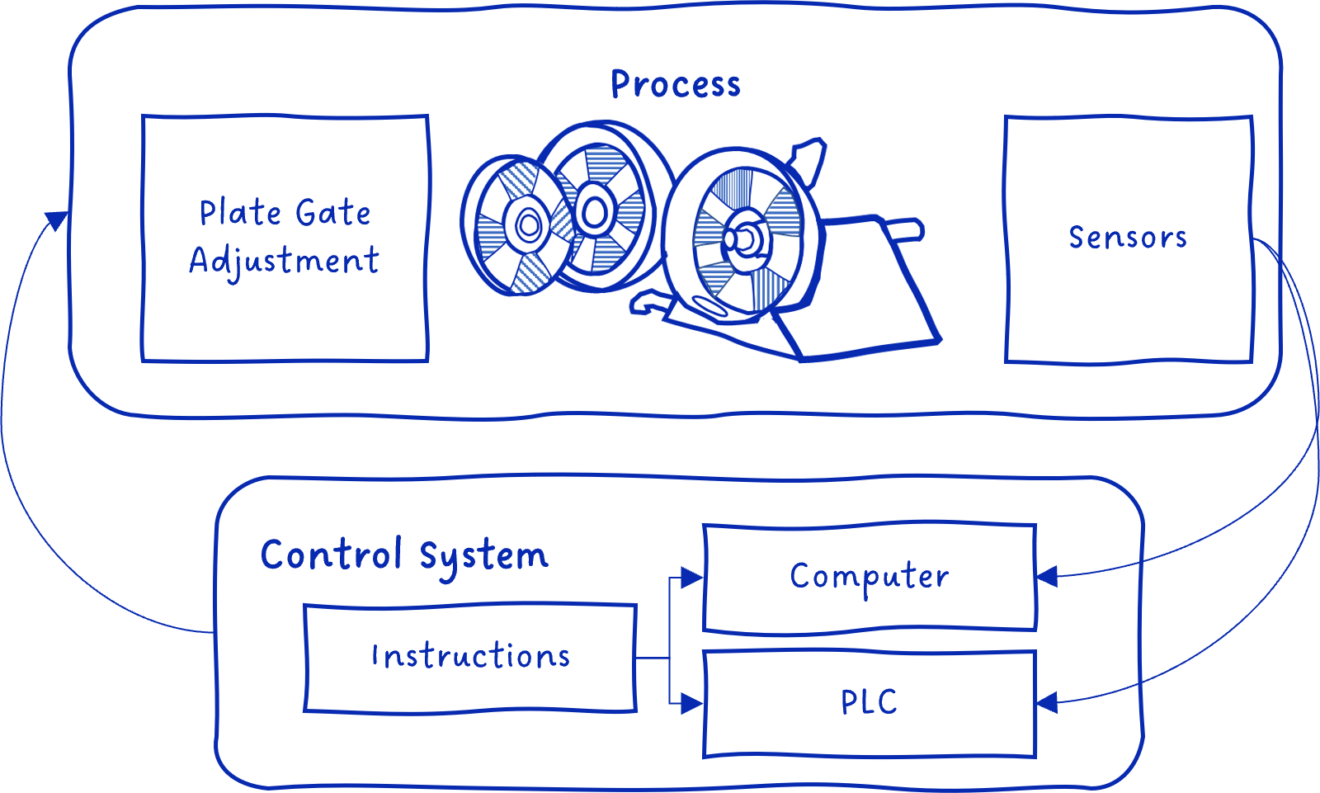

More precise control over the refining process, results in less waste, higher yield and reduced production costs. Easier said than done.

The Satron Lumina VCF provides real-time data on the pulp's degree of refining to support...

- Horsepower-days per Ton control

- Refining Target Freeness Setpoint control

Whether you are doing an energy balancing act or adjusting plate gap to maintain the target freeness, real-time data supplied in a reliable manner is mission critical. What does real-time get you?

- Adjustments to hit the sweet spot - minimizing energy use while ensuring the pulp is of the right quality

- Data needed to fine tune process leading to less waste from off-spec production

- Abnormal situation detection enabling proactive maintenance.

- Instantaneous comparison of current freeness levels with target levels

- Energy optimization avoiding excess usage from over-refining and avoiding inferior quality from under-refining

Footprint of an Inline Probe, Because it's a Probe!

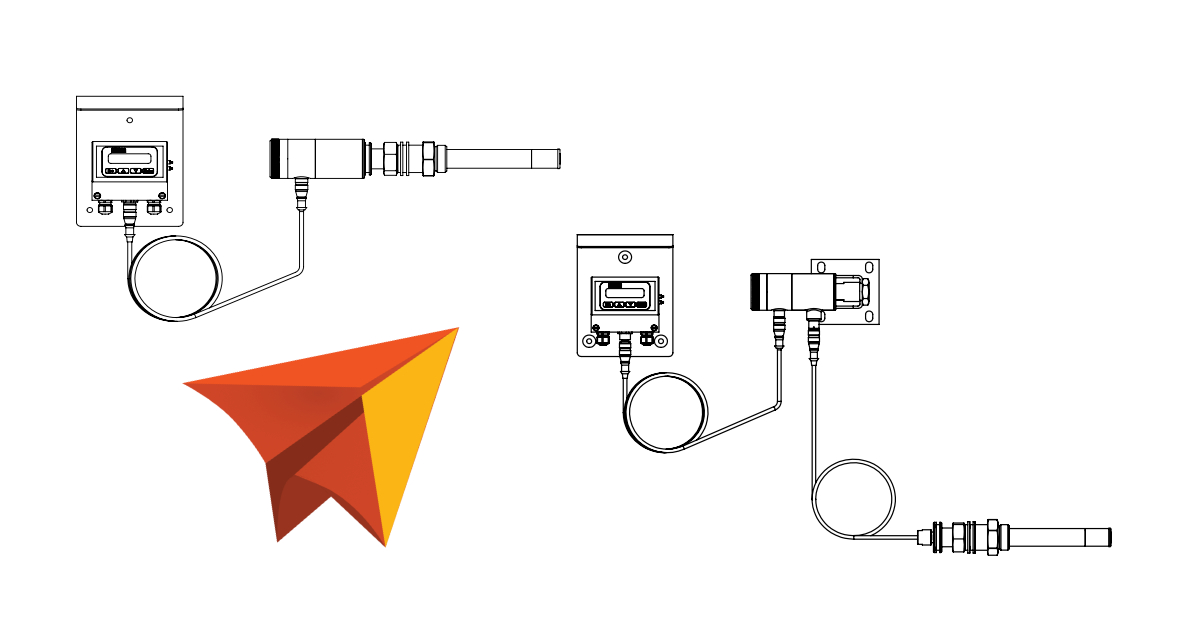

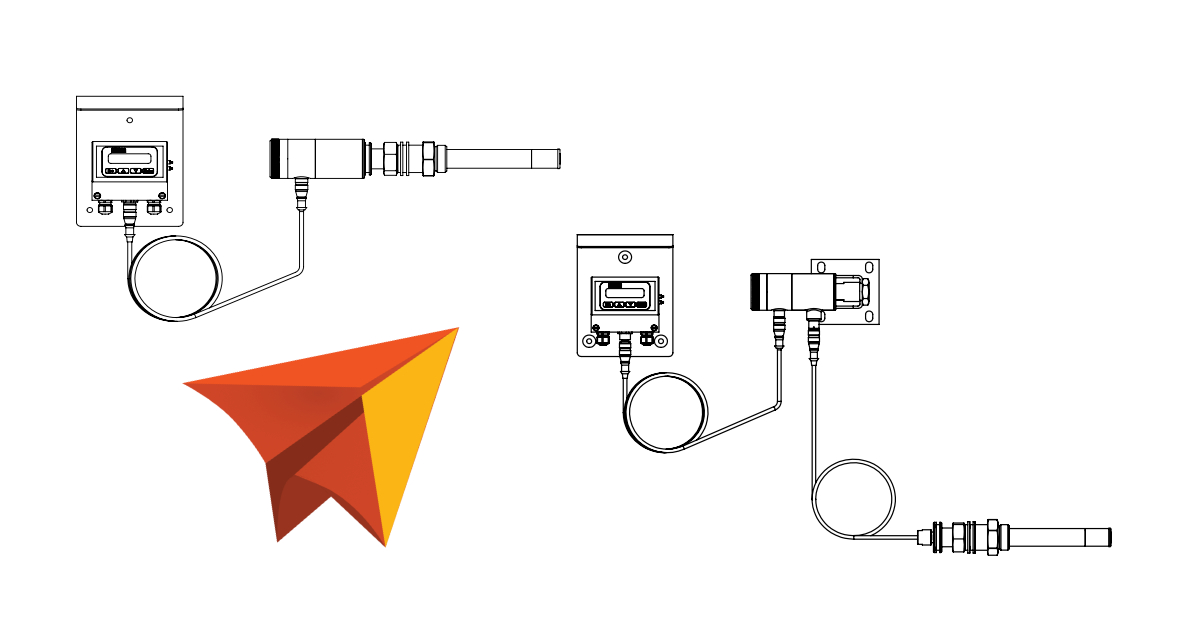

What you'll need for a real-time freeness transmitter

- Insertion point

- Installation of probe into the flow of the pulp

- A location for the RDU/enclosure and supply power

- Sampling and Calibration

- Connectivity to control system

- Examine it during an outage

Skip the Robot Infrastructure, Get the Freeness Values

What you'll need for a robot analyzer

- Insertion points

- Vibration-free, temperature controlled environment, that is dust-free and well ventilated

- Connectivity to control systems

- Water supply, and drainage required for sample dilution & cleaning, and wastewater drainage

- Access for personnel and equipment because robots require frequent maintenance for optimal functioning

- Human resources, either your own people or an annual support contract to bring in the robot's minders.

- Sampling and Calibration

- Safety infrastructure like power cut-off, electrical hazard protection, compliance with regulations and standards

Continuous With Little to No Maintenance

Most important element is you. Good sampling, following standard procedures at the beginning, means great calibration

Most important element is you. Good sampling, following standard procedures at the beginning, means great calibration- Latest LED-based techniques using multi-frequency light transmits strobes of light into the pulp and measuring the back-scatter characteristics

- Flexible configuration with a standard measuring probe or remote measuring probe

- Here at WeHAP, we've always got a plan (that's our motto, by the way: "We Have A Plan"). And our plan is to help you make the most of your pulp processing.

- So, what do you say? Join us on this fascinating journey through the science of recycled pulp processing by becoming a subscriber. Remember, at WeHAP, we're always looking forward, and "We Have A Plan."

Most important element is you. Good sampling, following standard procedures at the beginning, means great calibration

Most important element is you. Good sampling, following standard procedures at the beginning, means great calibration

0 Comments