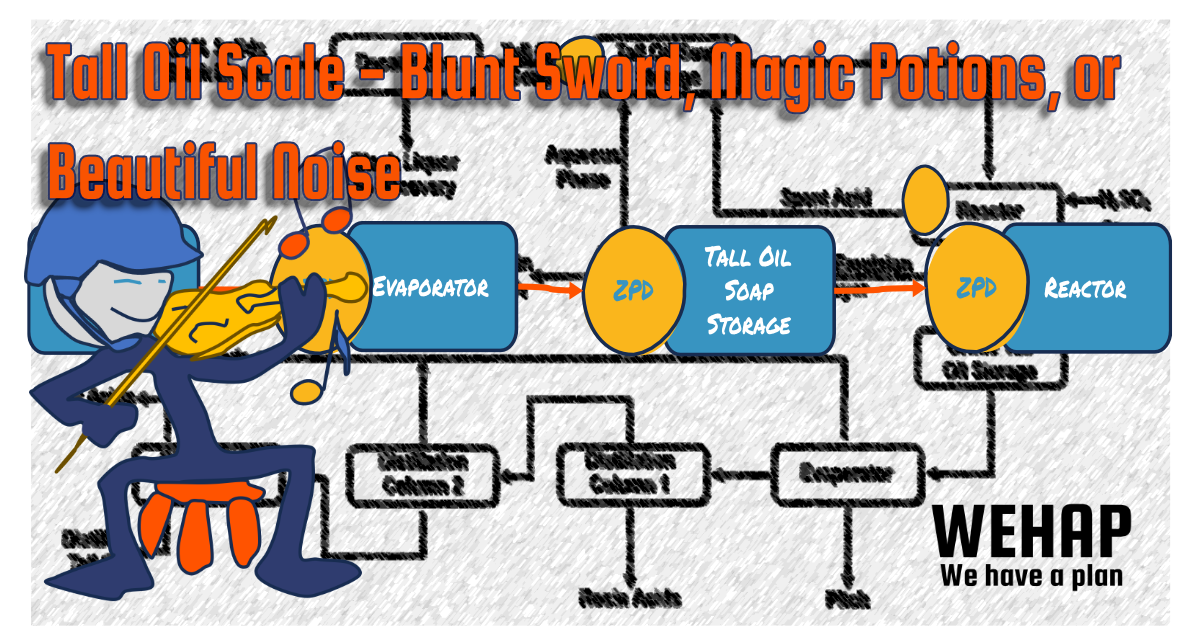

How do you improve the efficiency of crude tall oil (CTO) separation characterized by metrics such as the purity of the separated oil, the volume of oil recovered, and the consistency of the separation process. Scale formation in the soap skimming tanks and black liquor evaporators, and in reactors pose a threat to your efforts.

Big Money in CTO

There's big money in valuable fatty acids, resin acids, and unsaponifiables from CTO, so the level of profitability from efficient separation , higher yield, waste reduction is on process engineering skils.

Methods for removal

Traditional mechanical and chemical methods of scale prevention and removal in Kraft processes are akin to using a blunt sword and a double-edged potion... with nasty side effects.

What are your options for dealing with reduced heat transfer efficiency, clogged pipes, a decrease in separation efficiency., diminished quality of the recovered oil recovered, maintenance downtime and energy consumption?

And now the Beautiful Noise...Ultrasonic scale prevention. This approach uses high-frequency sound waves to disrupt the scale formation process. The sound waves create micro-vibrations and cavitation (the formation and collapse of an army of tiny bubbles) in the liquid, which can prevent scale particles from forming or adhering to surfaces. This method is like using sound waves to break apart and disperse a hard, clingy mob of scale particles who are starting to gather and block a pathway.

Blunt Sword

Mechanical scraping, the blunt sword in your cleaning arsenal, is a brute force approach that often leaves behind a trail of destruction. It's like inviting a bull into a china shop to catch a mouse; while the mouse might be gone, so is the shop's delicate inventory. The abrasive nature of mechanical cleaning can damage the very infrastructure it aims to protect, causing micro-abrasions that become havens for future scale formation, an ironic twist in the tale of scale.

Potions with side-effects

On the flip side, chemical treatments, the double edge potions, promise a less invasive route to scale dissolution. However, these chemical concoctions are like making a deal with a sea witch. The immediate effects may seem magical, as scale deposits dissolve and flow rates improve, but the long-term consequences can be dire. The harsh chemicals not only pose environmental hazards, but also threaten the integrity of the process lines and vessels. Over time, they can corrode the metal, weakening the backbone of the tall oil processing system. Furthermore, these chemicals wage an indiscriminate war, not only attacking the scale but also the equipment and potentially altering the quality of the tall oil itself.

The Beautiful Noise

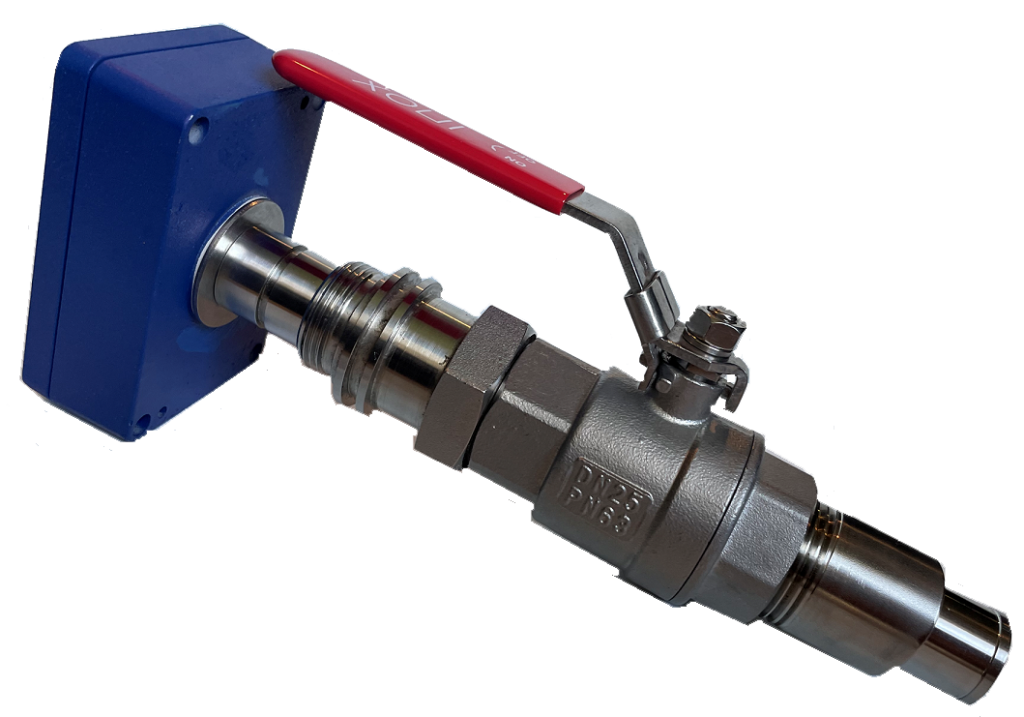

Ultrasonic scale prevention emerges as a game-changer in this scenario. This innovative technology employs high-frequency sound waves to prevent the crystallization of scale-forming minerals, thus inhibiting scale buildup in critical areas of the tall oil separation process. By keeping the tanks and evaporators scale-free, continuous, unintrusive ultrasonic scale prevention ensures that the separation process remains efficient longer, with a consistent flow rate and temperature, which are crucial for optimal tall oil recovery.

The application of ultrasonic technology in tall oil separation not only enhances the efficiency of the process but also contributes to the sustainability of pulp mill operations. It reduces the need for chemical scale inhibitors, minimizing the environmental footprint of the process. Furthermore, by maintaining optimal conditions for tall oil separation, this technology helps in maximizing the recovery of high-quality tall oil, boosting the profitability of pulp mill operations.

The integration of ultrasonic scale prevention in the tall oil separation process marks a significant advancement in pulp mill technology. It addresses the critical issue of scale formation, ensuring seamless operations, and superior separation efficiency. As the industry continues to evolve, such innovations underscore the commitment to efficiency, sustainability, and quality in pulp and paper production.

Financial Benefit of Ultrasonic Scale Prevention & Removal

The combined effect of improved efficiency, product quality, and reduced maintenance costs translates into significant financial savings for tall oil producers. By adopting the ZPD solution, facilities can expect a noticeable improvement in their bottom line, driven by lower operational costs and higher product value.

More Information: [email protected]

To set up conference call: [email protected]

0 Comments