So what is this a groundbreaking technology is going to do for me?

This blog delves into the process you and ultrasonic technology experts will use to determine the feasibility and return on investment (ROI) by implementing the state-of-the-art Ultrasonic Scale Prevention and Removal system, ensuring that you not only enhance their operational efficiency but also secure significant financial advantages.

Understanding the ZPD Solution

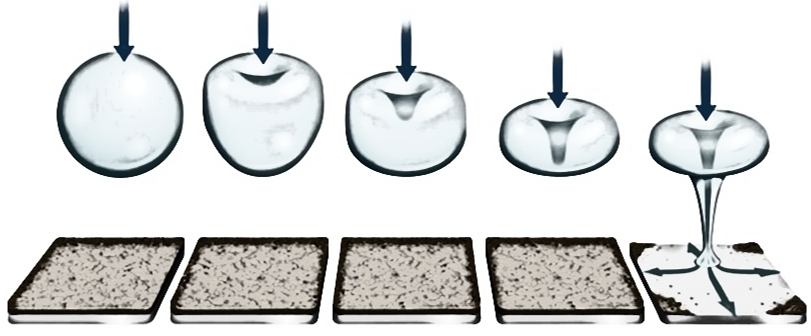

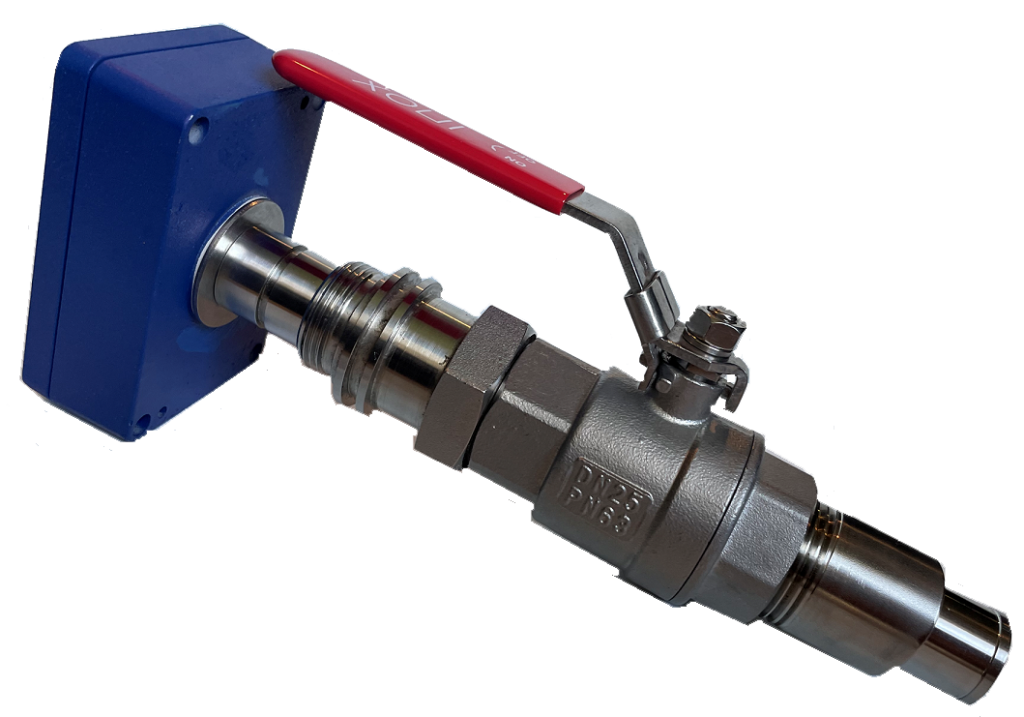

At its core, the ZPD solution harnesses the power of ultrasonic waves to prevent and remove scale buildup without halting production or resorting to chemicals. The system comprises three main components: the transducers, software, and monitoring services, all of which work in tandem to offer a comprehensive scale management solution.

Feasibility Analysis : Tailored to Your Needs

The first step in is a thorough feasibility analysis. This involves a detailed assessment of the client's existing infrastructure, scale challenges, and specific industry requirements. By examining factors such as the type of scaling, the composition of the liquids involved, and the configuration of the system, Altum crafts a tailor-made solution that addresses the unique needs of each client

ROI Calculation: A Conprehensive Approach

Determining the ROI of the ZPD system involves a holistic examination of several factors. Altum considers the cost savings from reduced downtime, decreased need for chemical treatments, and the extension of equipment life. Moreover, the increase in production efficiency and energy savings contributes significantly to the overall financial benefits. This comprehensive ROI analysis ensures that clients have a clear understanding of the potential cost savings and efficiency gains from implementing the ZPD system.

Implementation and Results

Implementing the ZPD system is seamless and non-intrusive, involving the strategic placement of ultrasonic transducers along the affected areas. The software-driven operation allows for real-time monitoring and adjustments, ensuring optimal performance. Clients can expect not only a significant reduction in scale buildup but also an improvement in overall process efficiency.

Reducing Task Load and Enhancing Processes

One of the key benefits of the ZPD system is its ability to reduce the manual labor and maintenance typically associated with scale management. This not only alleviates the task load on personnel but also allows for a more streamlined and efficient operational process.

A Sustainable and Profitable Solution

By providing a chemical-free, energy-efficient solution to scale management, ZPD system aligns with sustainability goals while delivering tangible financial benefits. The ROI extends beyond immediate cost savings, contributing to long-term operational efficiency and environmental stewardship.

| Fouling prevention in Black Liquor Evaporators | €730K/year productivity increases €120K/year operation uptime €180K/year energy savings; |

| Fouling prevention in Red Liquor Evaporators | Time between washes increased 60% Evaporation rate increased >6% Operational uptime increased by 25% |

| Fouling prevention in Black Liquor Heater | €500K/year productivity increases €235K/year in operational uptime €480K/year energy savings Stabilized flow rate with overall flow rate improvement of 5% Overall stabilization of temperature Original production efficiency maintained for 8 weeks without additional steam |

| Enhancing Tall Oil Separation | €1.2M/year productivity increases €150K/year operational uptime €90K/year operational cost savings Crude tall oil yield increased 4% Diminished use of sulfuric acid Increased safety from decreased manual cleaning |

Conclusion

This meticulous approach to determining the feasibility and ROI of the ZPD Ultrasonic Scale Prevention and Removal System ensures that clients receive a solution that is not only effective but also financially advantageous. With Altum, industries can look forward to a future where scale management is no longer a hurdle but an opportunity for efficiency and profitability.

For More Information: [email protected]

To set up conference call: [email protected]

0 Comments