Say "So Long" to that nightmare Robot Analyzer... or at least have some data while you are fixing it.

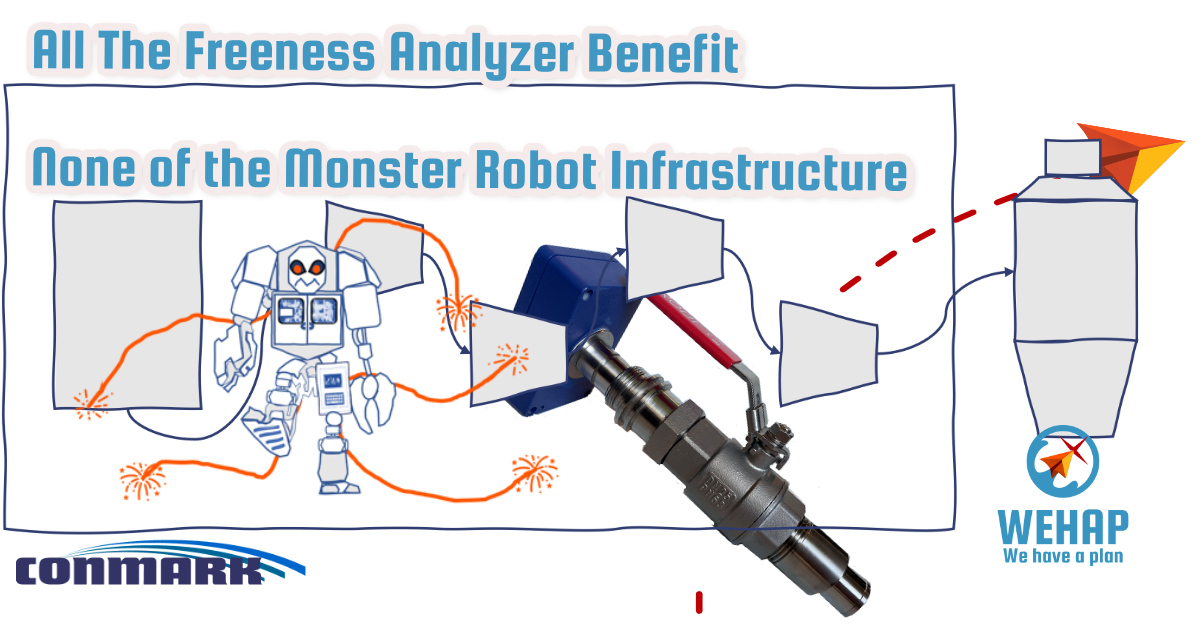

The ProEye 100 calibrated for Freeness will fulfill the crucial Stock Prep quality role providing accurate readings to support your control strategy.

Why use an LED-strobing analyzer:

- No Robot Analyzer Infrastructure - You get to skip the sample lines and constant maintenance.

- No Consumables - The probe, the cables, the RDU and your measuring Freeness.

- The objective of a freeness measurement is realized with a robust in-line, low maintenance probe:

- Improved/Consistent Product Quality: Reduce waste, returned/reworked product, and better control influencing final properties, such as strength, density, and smoothness.

- Efficient Chemical Usage: Minimize waste and save cost on absorption & retention additives from more efficient application.

- Predictive Maintenance: Real-time data to identify trends and early warning.

- Improved Environmental Impact: Optimize energy usage and reducing waste, reduce environmental footprint,

The ProEye 100 provides a small footprint, robust alternative to large, expensive, and hard-to-maintain analyzers.

The ProEye 100 is a dual channel analyzer that can be calibrated for ten (10) different properties.

With no moving parts and no sample lines, these analyzers are inserted directly into process lines and installed in turbulence so that frequent/regular lens maintenance is not required.

The analyzer can be removed while the process is online. With respect to safer access/removal these analyzers are compatible with mounting and service valves enabling safe removal without stopping the process or draining tanks.

Want to toss out the old robot? Need an analyzer for when the monster goes down? Want to find out more about more about ProEye 100 and ProEye Cs LED-strobing analyzers Click Here

Want to get specs or talk pricing and/or installation? Contact [email protected]

0 Comments