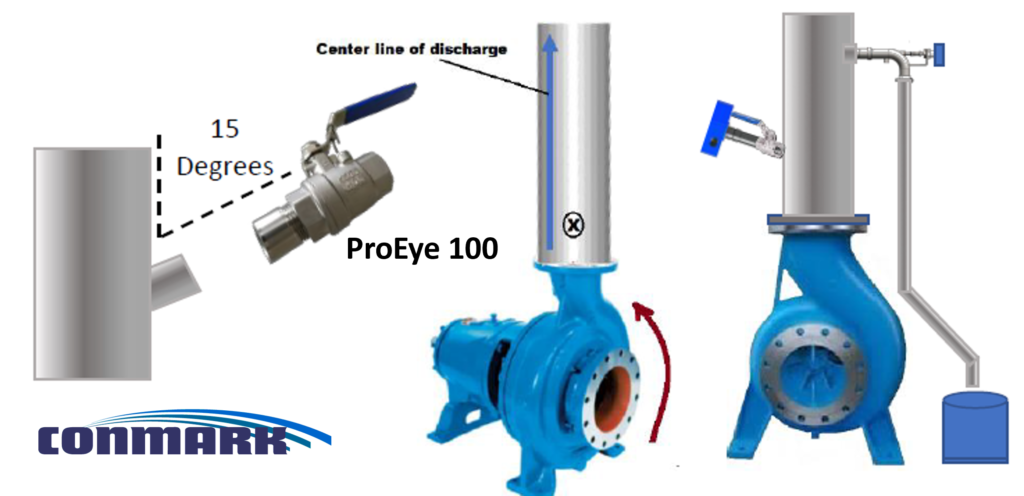

ProEye installation

Requirements for installing ProEye 100 LED-strobing analyzer

- Location and determination of the probe type.Insertion point creation

- Sampling for calibration

- Post installation performance comparisons

- Probe examinations during planned outages

Pain you are avoiding

- Infrequent Kappa updates to the process

- Hiring more personnel to do more lab sampling/analysis from more advantageous locations

- Finding a location that is vibration-free, temperature controlled environment, that is dust-free and well ventilated for the robot

- Finding a location that provides access for personnel and equipment because robots require frequent maintenance for optimal functioning

- Installing and maintaining water supply, and drainage required for sample dilution & cleaning, and wastewater drainage for the robot

- Annual support contract

- Transmitter measurement drift

What To Expect the ProEye 100 configured for Kappa measurement

- Precision based on sampling and calibration; updating the calibration is easy.

- Recalibration only when a significant change to the process

- Little to zero maintenance

- Better alarm design

- Higher precision operator screen

- Higher frequency, smaller adjustments for automation control

Operators with alarms and displays supported by real-time data are going to make good moves. Automation control is going to be possible or be better with a continuous

#ContinuousKappaUpdates #ProEye100 #ProEyeCS #PulpMillOperations #ProblemSolving #KappaMeasurement #PulpProperties #StockProperties

Want to read more about a topic within this post? Click a tag.

0 Comments