So, what are we talking about? We're suggesting a reduction cleaning time with real-time turbidity measurement where a conductivity measurement is not enough.

Take yogurt process for example. With the VO sensor you can safely shorten the filling machine, for example pre-rinse cycle by reducing configured safety margins or eliminating unnecessary human intervention, leading to overall reduced CIP time. This leads to a filler machine being ready for the next product or stage… sooner.

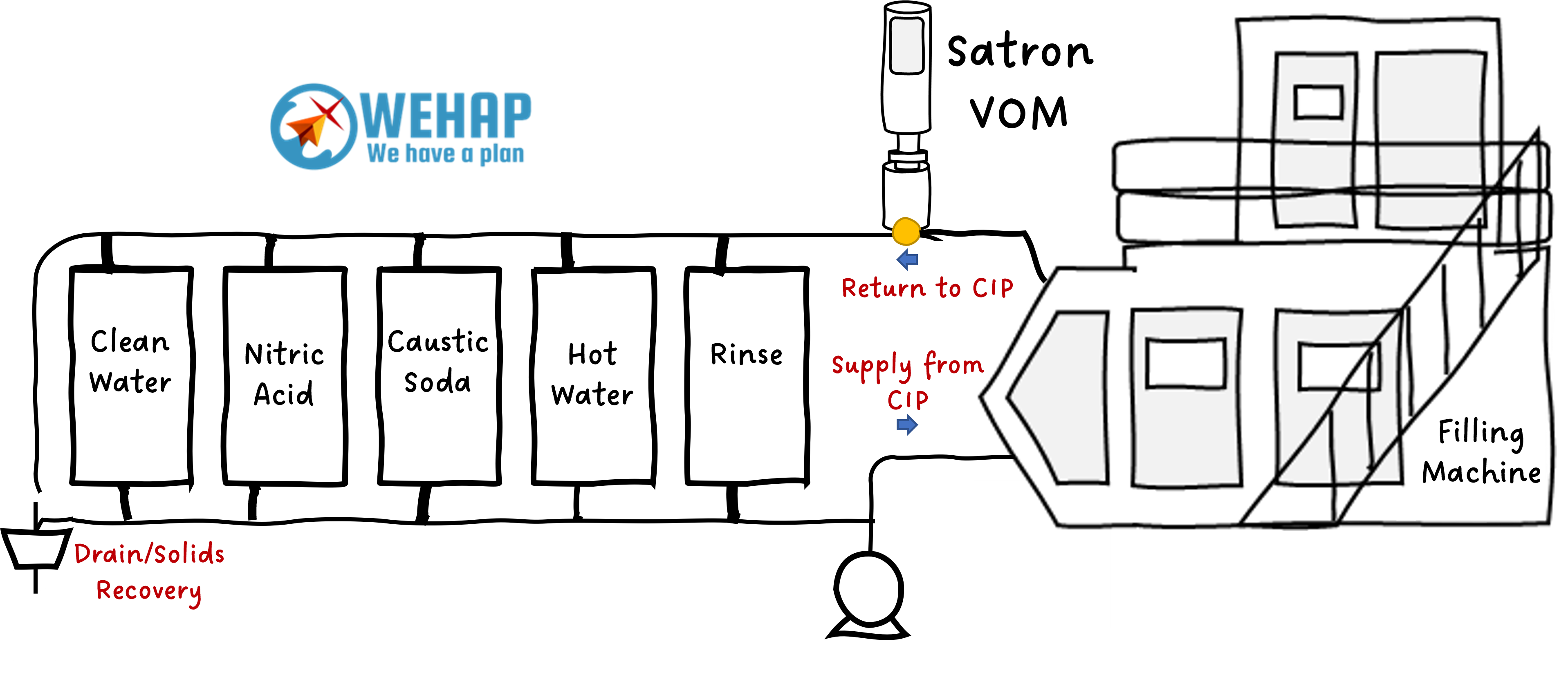

Additionally, chemicals used in cleaning the filling machine are monitored so chemicals returned to their respective tanks are not contaminated and can be safely be reused.

How is it done? Install the VO at the filling machine CIP return line, connect VO to control system, create the rules and settings… you are done. This is basically the same for all milk process manufacturing.

Too Easy? Let’s talk about it.

0 Comments